Zinc die casting had become an indispensable process in the automotive industry. The process enables create high-precision, durable, intricate geometies and cost-effective components. With its unique properties, zinc alloy die casting contributes to the efficiency, safety, practicial applications and aesthetic appeal of modern vehicles. Let’s explore applications of zinc die casting in the automotive industry…

DIE CASTING DESIGN AND PRODUCTION CERTIFIED SUPPLIER

Trusted by Engineers and Purchasing Leaders at Some Known Cooperation

Trusted Casting part Business Partner

Tscasting Technology can make die casting parts, these casting die products have been used in many fields. Especially many metal parts for machines are die casting metal parts , Their manufacturing process is also different due to different material is chosen and product structure is designed.

Good Solutions for Plastic Injection Provided

Tscasting Hardware Technology Produces Plastic parts to match with zinc die casting parts . As one of quite die casting factories , We set up a streamline of plastic part manufacturing. Include of plastic part design for injection molding, plastic injection part testing and mass production.

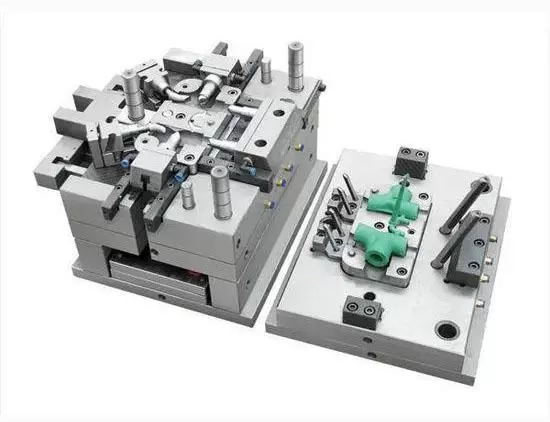

Effective Solutions for Mold & Die Process

Tscasting Hardware Technology Provide Mold Design and manufacturing , Whenever Metal casting die and plastic injection molding tool. The die casting factory have one stop mold solution. Equipped with advanced machines and well-experienced engineering technique team.

About Us

Comprehensive Die Casting Factory

Tangsheng Hardware Technology Co., Ltd. was one die casting factory, which is specializing for die casting products design and production and matching plastic parts. It has a set of matured manufacturing technique and perfect supply chain system. The company can provide molding designs for all parts, first sample make, assembly testing and function testing etc. The company provide a stop service to business partners from automotive industry and electric communication industry.

Latest Projects

From the following Classic Cases, The die casting factory let you know of Zinc alloy casting process and Plastic injection production in the industrial factory, serves nowadays popular automotive industry and Electronic Communication many fields. Zinc alloy is so easy to be cast and shaped into casting parts at lower temperature. Compare to other metal material, It is made into high quality products at cheap cost.

Car Key Case

Zinc alloy die casting have become an indispensable part in current society, whenever in our daily life. Various Car key case are made from zinc alloy.

Portable USB Charger Panel

A car USB charger display panel can indicate clearly that how status are these ports built in, user can adjust what functions is for them. That is beneficial to use it when driver and users want to charge electricity power to mobile phones.

Switch Box

The Switch box is made from Zinc alloy material, which Adding aluminum to zinc increases the alloy’s strength and hardness while also enhancing its resistance to corrosion.

Camera Housing

This is a precision zinc alloy casting project, it is a full camera housing, contain the fixed brackets for all electric circuit board and components for running as a monitoring and surveillance camera

USB hard disk drive Housing

Application of USB flash drive disk have been used widely. This small size thing, can bring more convenience and portable to you, but the core of it is electric circuit and chips, which need a durable and strong cover to protect the core parts

Wireless Charger Base

This is wireless charger supporting base, which is made of zinc alloy. It can be installed on the charger so that recharge electricity power to smart device

Services

What We Do

Mold & Die Design And Manufacturing

Tscasting Technology Designs Casting die and plastic injection Mold in accordance with client’s requirement, Manufacture and Modify mold & die until the client is satisfied with the result.

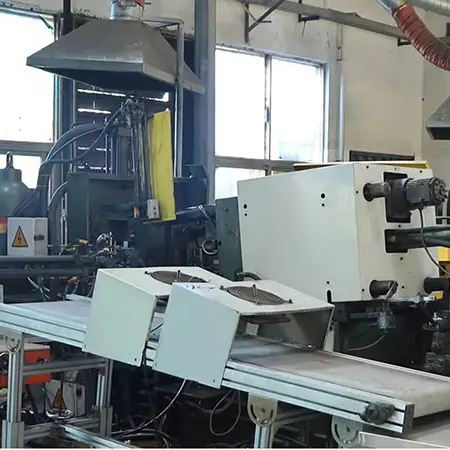

Injection Molded Plastic Parts

Tscasting Hardware Technology produces Injecting plastic parts with our own manufacturing plastic injection molding, Process TPU material soft water proof mat and some of auto parts , such as car key cover and electronic components. Also provide custom plastic parts available.

Die Casting Parts

Tscasting Technology Processes zinc alloy small and medium size parts. Involve of auto and communication fields. This is just our advantage for casting zinc alloy parts. Our regular business partner have a good proud for us. Accept any custom die casting parts.

Rapid Prototyping Service

This machine is used for some clients who want to have a look at prepared sample before manufacturing mold. Especially various plastic injection parts, with 3d pring machine can save more cost and labors.

Casting metal parts polishing

Tscasting Technology addresses a post process for metal parts. For the rough surface of zinc alloy casting parts, it is indispensable part, most casting parts and metal products will be polished before outsourcing.

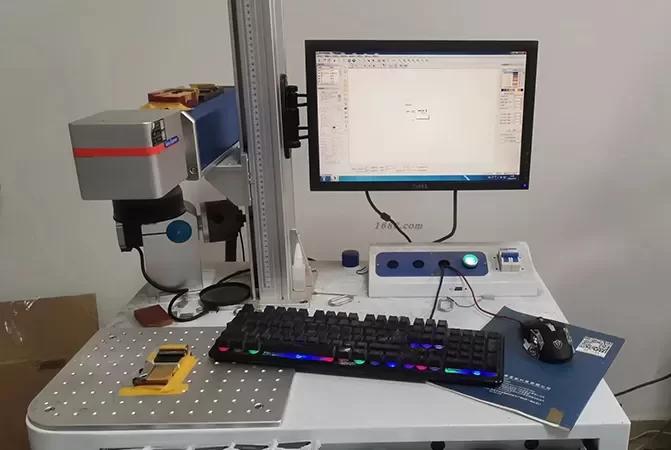

Precision Laser Engraving

Tscasting Technology provides laser engraving logo and pattern on the surface of products, regardless of plastic parts or die casting part and metal products. Largely improving an appearance of products .

Casting part CNC Machining

Tscasting Technology possesses post process for die casting parts, As zinc alloy casting part, but also it is medium and small size, Removing some rough areas and parting lines though Precision Cnc machining center.

Casting Part Deburring

This is simple post process for die casting parts, check each rough casting part, workers request removing some sharp edges on the die casting part, removing the flash on the parting line and making the surface of parts smoother.

Installment Test and Package

Tscasting Hardware Technology has a comprehensive dept, All parts are reached at this place after passing a few processes. whenever metal parts or plastic plastic, operators begin to have a right installment and testing under a right guideline.

Subscribe Us , Attention More Any Time

Quality Control

Tscasting Technology executes strict quality control, Because quality is survive base for an enterprise, Only provide high quality products to client, we can achieve an good reputation and broad market. The company regards quality as the core of progress and development. All products should be testing and checked before deliver them to any client.

Latest Blogs and Insights

The quite strength die casting factory create some successful project cases, show our production experience and shares