Custom Die Casting

In our daily living and working, We can often get in touch die casting parts. These casting die products have been used in many fields. Especially many die casting parts are used for machines and equipment. Their manufacturing process is also different due to different applications. What we usually learn is more common manufacturing process , which is zinc alloy die casting and aluminum alloy die casting. Because the two kind die casting parts are the most widely. In another one, copper casting and stainless steel casting is belong to die casting manufacturing process. But they need be cast into parts at high temperature. No matter, These metal casting parts should be made in accordance with customer and market’s requirements. So custom die casting parts become more and more popular in current society.

What is Custom Die Casting ?

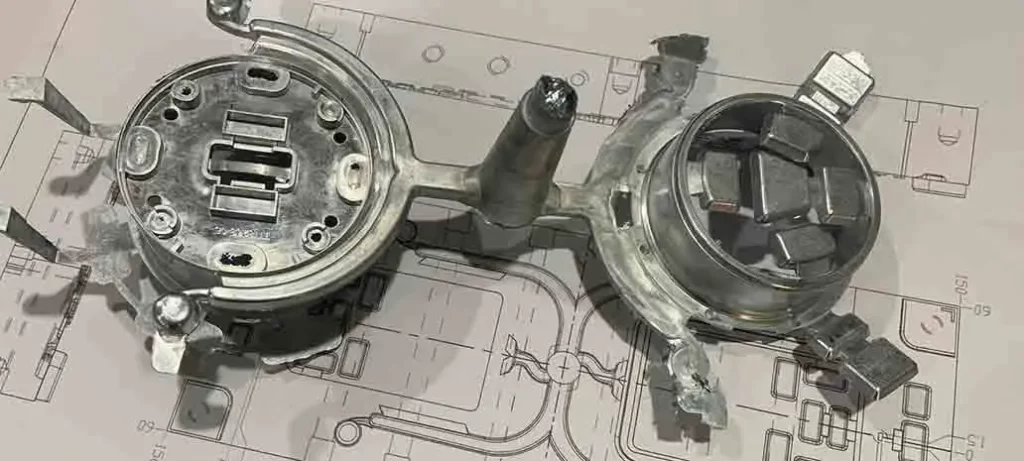

Custom die casting is specific process of manufacturing metal components, in which using die casting technology tailored to meet specific requirements or unique designs. It contains the design of custom product model and creating precisoin molds or dies. Custom die casting projects have OEM and ODM services. Client provide their drawing and design plan to their supplier, hand to their supplier to finish the product that they desired, this is called as OEM project. However ODM project, which means the supplier design and produce the custom die casting component, depends on client conception or pictures. Whenever, depends on customer’s specific requirements, Supplier should produce high-quality custom die casting components.

Features of Custom Die Casting

- Tailored Solutions: The client present the design requirements and design plan to the supplier, and require the supplier to design the molds or dies to produce the custom component with the specific requirements, so that ensuring the component fits seamlessly into their application.

- Best Material Option: Among various materials like zinc, aluminum, magnesium, or their alloys materials, the manufacturers can choose the best alloy material to make custom die casting components with specific requirements.

- Tight tolerance Product Dimension: Alloy die casting components all have a high accuracy dimension and fine surface finish, So the steel die should be processed by high precision machines, such as milling, turning and cnc machining and EDM process.

- Diversity Surface Finish and Aesthetics: These custom die-cast parts can be finished with various surface finishes, afterwards, they need minimal post-process. Additional treatments like polishing, plating, or painting to meet appeal decoration or functional needs.

- Specific Properites And Inspection Standard: The client require the casting part has some specific properties, such as stronger corrosion resistance, endure some acid environments and moisture air and marine bench, The custom die casting part should be inspected through salt frog testing.

Custom Cold Chamber Die Casting

Cold chamber die casting have been called as main industrial manufacturing method. It is ideal for higher melting points metal alloys, such as Aluminum, steel, copper, iron and stainless steel. die casting manufacturer can make custom die casting parts with specific function and aesthestical apperance in automotive and mechanical industries using these high melting points metal . These custom die castings have all the below significant characteristics.

Tailored And Personlized

Custom die casting should be tailored and personalized until meeting the specific requirement or unique design. The manufacturing process may have an expensive cost, but it can meet the demand of the client, The custom die casting need produce low volume products.

Best Material Option

Choosing the best material will decice the cost of precise die, especially custom aluminum die casting component can be processed in high efficiency. So die casting manufacturer should employ best material aluminum to make high quality custom aluminum die casting component.

Specific Requirement

These Custom die castings require being satisfied with some specific requirement from the client. The aluminum custom die casting parts are used for automotive, aerospace, and other industries needing lightweight components. They need integrated structure and strong mechanical properties.

High Waste Material Acceptable

Custom die casting processes custom die casting parts, may generate more defective products. This causes high waste material during manufacgturing process. So in general term, the client can accept high waste material and pay more money to the supplier. And only require high quality custom die casting components.

Custom Dimensions and Complex Geometry

Aluminum alloy die casting has high dimensional accuracy. Custom die casting need accurate dimensions and specific requirement process, and ensure the accuracy dimensions of the part and personalized geometry requirements. Custom die casting makes the structure and design of mold & die more complex.

Cold-Chamber Die Casting Machine

In cold-chamber die casting, the molten metal is melted in a separate furnace. The molten aluminum is ladled into the injection system of the die casting machine when begining casting the aluminum die casting parts. Then injected into the mold using a high-pressure plunger. and cooled and shaped, ejected the shape rough casting components from the die.

| Machine Name | Brand | Equipped with Robot hand | Machine Type (Tons) | Quantity(set) |

| Cold chamber die casting machine | LiJin Brand | Yes | 200 tons | 2 |

| Cold chamber die casting machine | LiJin Brand | Yes | 320 tons | 2 |

| Cold chamber die casting machine | LiJin Brand | Yes | 400 tons | 1 |

| Cold chamber die casting machine | LiJin Brand | Yes | 500 tons | 1 |

Custom Hot Chamber Die Casting

We choose lower melting points metal alloys to make custom die casting components and ensure meeting client’s specific requirements. Such as zinc, magnesium, lead and tin alloys. As one professional metal die casting manufacturer, and possess advanced die casting machines and skilled-well technician and comprehensive management system to make various custom die casting components across many industries. Its features reflect the below key points.

Material Options

Custom die casting project have an option for castable metal alloys, To be satisfied with the specific requirement of the client, we provide these lower melting points metall alloys for the right choice of client, such as these metal alloys like zinc, magnesium, lead and tin alloys.

High Precision And Superious Surface Finish

Custom die casting components all require tight toleerance dimensions and fine surfface finish when it is as-cast finish. We choose advanced die casting machine, high precision tooling steel die and strict quality management regulation to produce high precision die casting component with superious surface finish.

Complex Geometries And Thin Walled

These low points metal alloys all have excellent ductility and good fluidity. In die casting process, these custom die casting components with complex geometries and thin walled is processed easily under high pressure. But the custom casting die requires more preciser process.

Lower Energy Consumption

Melting the metel alloys, the more higher points metal , the more lower energy consumption. These lower melting points metal alloys require lower engergy consumption when they are molten. Below 430 degrees, they can be molten, and reduces electrical energy consumption during mass production.

Fast Cycle Times

The molten metal is held in a gooseneck chamber within the machine, allowing for rapid injection. Ideal for high-volume production due to quick shot-to-shot cycles.

Custom Zinc Die Casting Is Easy To Form Intended Part And Cost-Efficiency

Zinc die casting parts are easy to be made and lower cost, compare to other metal material ,such aluminum , iron and copper. Since zinc alloy melt point is so lower, at about 420 degrees. From this point only, the zinc alloy casting parts is best choice and cost efficiency. Meanwhile, Zinc die casting offers a fast cycle cast in mass production. The lower melting points and fast cycle cast will reduce the overcost of zinc die casting, although the cost of zinc alloy material is higher than one of aluminum material.

Also people found that zinc alloy material, many original metal parts in many fields have been replaced by zinc alloy casting parts. Likes lock, door handle, zipper head and some display gifts etc. These custom zinc die casting parts may be electroplated by chrome, nickel , brass and gold, it will show a beautiful appearance to you. In some applications, it can replace copper parts. Of course, someone think they can do zinc alloy camera housing , instance of aluminum housing that cooling heat faster. If you want to look for a professional custom zinc casting factory, we will provide our consideration service and satisfied products to you.

Hot Chamber Die Casting Machines

This should be a simple and straightforward processing procedure, that is zinc alloy material is pressed into metal die under high pressure. And then formed parts and be cooled and solidified shaped parts. As custom zinc alloy die casting , which can be formed into metal parts at reasonable temperature. About 420 degree at the temperature. The melton pool is integrated with die casting machine, and drive the plugin to melton metal into the casting die quickly, and have a fast casting cyle, suitable for mass production in high efficiency.

| Machine Name | Brand | Equipped with Robot hand | Machine Type (Tons) | Qty(set) |

| Hot chamber die casting machine | LiJin Brand | Yes | 50 tons | 2 |

| Hot chamber die casting machine | LiJin Brand | Yes | 80 tons | 2 |

| Hot chamber die casting machine | LiJin Brand | Yes | 88 tons | 1 |

| Hot chamber die casting machine | LiJin Brand | Yes | 160 tons | 1 |

Why Choose Us

Our Services

Plastic 3D printing and die casting Prototypes-rapid prototyping services

Sophisticated Engineering Team

With their enrich engineering design experience, Engineers design the physical model or prototype in accordance with client desire and a general conception. And can collaborate with the client, and aim to a consistent target. Optimizing prototype process and achieve deliver the first sample to the client in short time, within a few hours and days.

Advanced Precision Machinery

Advanced precision machinery include of Cutting, Grinding, EDM, CNC Machining, Tapping and Milling ect. With them, process precise injection molds & dies. Also optimizing and improving these precise molds any time. Using the precision mold to have a trial, and inject first sample. Whenever metal cast die or plastic injection molding, it should pass a serial comprehensive procedures.

Strict Quality Inspection

TscastingTech has a set of perfect quality control system. It handles raw material incoming inspection and outsourced processing incoming inspection. This ensures a steady products quality in mass production and reduces rework rates and material process lost cost and realize high efficiency production. Depends on different industrial specific quality level, some of finial products, exception of fitting the general quality standard.