Laser Marking on plastic is a precise and effective way. It can make permanent markings, logos, or text on the surface of plastic part. Moreover,this laser marking on plastic is clear, wear resistance and durable. Its operation is quite cost-efficiency, compare to Laser Marking On Zinc Die Castings. So laser marking process is also a kind of cost-efficiency effective approche that business men build their brand and promotions.

Choose The Right Laser Marking Machine, Set Up According Laser Engraving Drawing, Finish The Laser Marking On Plastic Project.

Laser Marking on Plastic Operation Guideline

1. Choose the Right Plastic Material

Not all plastics are equally suitable for laser engraving. Relying on our rich experience for laser marking on plastic parts over past decades years, We will recommend the blew some common plastic materials that work well. They include the below items:

| Material Items | Advantages |

|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Engraves to a frosted or slightly melted appearance, maintain good contrast with laser marking.Laser Type: CO₂ Laser (9.3–10.6 μm wavelength). |

| Acrylic (PMMA) | Engraves smoothly with a frosted finish, Laser Type: CO₂ Laser (best results at 10.6 μm). |

| Polycarbonate (PC) | generates high-contrast marks, high heat resistance, engraves with a slightly rough texture. Laser Type: UV Laser (355 nm) for clean marks. |

| Polyamide (Nylon) | Strong and wear-resistant, Laser marking creates durable, high-contrast engravings. Laser Type: CO₂ or Fiber Laser. |

| Polyethylene (PE) | Difficult to engrave, Requires special additives (e.g., LDPE with laser-sensitive pigments). Laser marking works best with UV lasers for high contrast. |

| Polypropylene (PP) | Can be marked with UV lasers (355 nm) for high precision,Chemically resistant, good for packaging and labels. |

| PVC (Polyvinyl Chloride) | Low-cost, widely used in electrical insulation and signage, Laser marks dark and clear with high contrast. |

| Requires special additives (e.g., LDPE with laser-sensitive pigments) | Some pre-doped with additives (e.g., LazerFlair) for high-contrast marks. Laser Type: Fiber or UV Laser (for high precision) |

We should choose the reasonable plastic parts and make laser marking on it , ensure if the plastic type is suitable for laser engraving. The above plastic material is favor of laser marking.

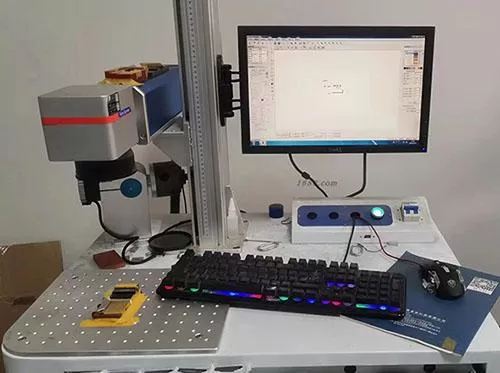

2. Select the Correct Laser Machine

Different type of laser machine can engrave different material and the depth of engraving you want. Also ensuring laser marking logos ,text and patterns must be clear and perfect. We should choose the right process from the follow methods.

CO2 laser has a power range between 10W and 100W. Typically used for plastic engraving, different plastic material, different operation options.

Fiber Laser can also engrave certain plastics but is more commonly used for both metals and hard plastics.

Diode Laser is suitable for light-duty engraving on plastics.

3. Prepare the Plastic Part

We should clean the place and area will be engraved, and ensure where not any oil, dirt and dust. If the part is small or lightweight, fix and secure the plastic part by using a jig or clamp to avoid movement. In order to achieve a high efficiency mass production, we can tailor custom jigs.

4. Set Up the Laser Engraving Machine

Adjust the focus of the laser beam according to the height of the plastic part. Then adjust the laser speed and power according to the type of plastic and the desired engraving depth. Requires Higher Speed, Lower Power for shallow engravings or surface marks. Lower Speed, Higher Power For deeper engravings. Typical Settings (these vary by machine and material): Acrylic: Power 40-60%, Speed 300-500mm/s. ABS: Power 30-50%, Speed 300-600mm/s. Polycarbonate: Power 50-80%, Speed 200-400mm/s.

5. Design the Artwork

Laser engraving machines generally work with vector file formats such as .AI, .SVG, .DXF, or .EPS. We use these software like Adobe Illustrator, CorelDRAW, or AutoCAD to create the design, draw vector files for engraving specifications. The design is appropriately scaled for the plastic part. Set the resolution (DPI) based on the level of detail required—typically 300-600 DPI for plastics. Invert Colors setting if needed. Defaultly the engraving process may interpret the design as black (engrave) and white (no engraving). If you need color pattern or text, you may do post-engraving process, painting and coating.

6. Start the Laser Engraving Process

Once everything is all ready, run the engraving process on the actual plastic part. According to the size and complexity of the design, this can work from a few seconds to several minutes on each plastic part.

7. Post-Engraving Finishing

After laser engraving, some residue or dust left on the surface of the part. we commonly use a soft brush or compressed air to clean them off. For stubborn residue, use typical isopropyl alcohol and a soft cloth. Check the engraving quality, Being sure it is clear, legible, and uniform. Improve the defect parts continuously until all of plastic part engraved acheive specific quality standards.

8. Optional: Reinforce the Engraving

If the engraving needs to reinforce the engraving mark, you can use paint and varnish to the engraved area. This is common when engraving plastic parts logos have a poor contract with the color of parts , other contract colors can be used to cover it and creat a fine contract colors. In some cases, a protective coating or varnish is used to enhance the durability and appearance of the engraving.