In current technology surging era, the automotive industry production scale is still spreading over the world. With the growth of the demand of automotive components, naturally the demand of automotive components zinc die casting is increasing accordingly. Now, please allow us to have a general predict to the automotive components zinc die casting market demand in 2025. With the increasing demand for lightweight and durable components is up continuously, zinc die casting in automotive industry is play its essential role in modern industrial manufacturing.

Zinc Casting Automotive Components Market Overview in 2025

In 2025, the global zinc die casting market has a significant growth. Being impacted by save energy and environmental protection in the globe. Especially in emerging economies, the demand for lightweight, cost-effective, and durable components was fueled in efficiency and more benefit to environment managemet. Whenever the need for fuel-efficient vehicles or Electric Vehicles, zinc die casting played a pivotal role in the production of automotive components. With its superior mechanical properties, ease of casting, recyclability and low production cost. Naturally zinc die castings can be applied in various sectors in automotive manufacturing.

Growth in Automotive Production

The automotive industry is still expanding globally in 2025, particularly in emerging markets like China and India. The demand for high-precision and cost-effective zinc die-cast components for engines, transmissions, and structural parts in Automotive manufacturing is big. This due to zin metal material special properties.

Shift Toward Lightweight Materials

Automakers were seeking ways to improve fuel efficiency and meet stricter emission standards. Some lightweight materials like zinc and aluminum alloys are selected. Zinc alloy is durability and formability, can meet the demand of some automotive components. Although aluminum alloy are most lightest, but it belong to porosity metal material. These aluminum die casting surface finishing is not easy to treat .

Increased Use of Zinc in Electrical and Electronic Components

Zinc die casting was increasingly used for automotive connectors, sensors, and housings. Especially on the centrel console of vehicle, where more datas need be displayed . As zinc components , can shield electromagnetic signal interference, and protecting electric operation system running well. And transmit more accurate monitoring datas to the centrel console.

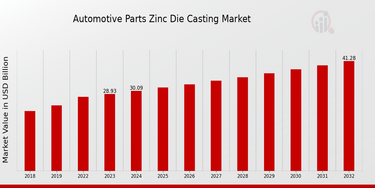

Global Market Estimates

Showing according to statistic, in 2025, the overall zinc die casting market was estimated to grow stably. With the rapid development of automotive automation functionality, vehicle monitoring system need more zinc die casting components to realize more monitoring functions. The automotive sector will contribute over 50% of the global zinc die casting market revenue at the time.

Global Market Distribution For Automotive Components Zinc Die Casting

Global Automotive Zinc Die Casting Market Size

In 2025, the automotive zinc die casting market was valued to reach USD 2.5 billion.The automotive sector accounted for 55-60% of the global zinc die casting market, These precision zinc die casting assemblies mostly used for sensor housing(can shield electromagnetic signal interference, and protecting electric operation system running well), interior decorative fitting, safety prenventive system locks and transsition system Counterweight parts etc.

Automotive Market Distribution In Globle

Asia-Pacific: Amount for over 40% world market share, massive automotive production in countries like China, India, and Japan. China, in particular, was the largest automotive production of vehicles globally, is creating a huge demand for zinc die-cast components. And more die casting manufactrurers to produce plenty of zinc die casting components to meet their demands.

North America: In United States robust production of light commercial vehicles and passenger cars. These newly automotive production lines need more custom zinc die casting assemblies to assemble. Also those specific requirement components with designed intrcate and precision dimensions is more easier to finish through zinc die casting process.

Europe: Focused on producing high-end fuel-efficency cars, Europe also has a steady demand for precision zinc die-cast components. Germany, as a leading automotive hub where more personalized sport car will be made to meet some global high end-users. Personlized automotive components are required. More high precision and creative zinc die casting components required.

Growth Rate

The automotive zinc die casting market in 2025 was growing at a CAGR of 8-9%. manufacturers moved toward lightweight and more efficient vehicle designs. need more precision and high requirement zinc die casting components. Especially the rise of AI intelligence technology, More vehicles need to be equipped with these creative functions. On cars Where many intricate sensor devices will be installed and monitoring and controlling the cars actions. The demand of Zinc die casting sensor housing may have a growth spurt.

Zinc Alloys Are Sustainabile and Green Eco-friendly Material

Zinc is 100% recyclable, and its use in die casting aligned with the automotive industry 2019s. It has a less carbon emmission and minimal wastage and confirm environmental protection. This was particularly evident in Europe and North America. So zinc die castings can be used widely in many industries.

Applications in Automotive Components (2025)

Different Compostion Zinc alloy Die Castings,Different Applications in Automotive different sectors. The best zinc alloy will be chosen among these Zamak zinc alloys, depends on the specific requirement and functionality of the zinc casting part, and cast to accordingly automotive components to assemble and play their performance.

- Structural Components: A leading European automaker can use zinc die casting for their engine mount brackets. These components provided excellent vibration damping and strength. Also it is durable,cost-efficiency and good heat disippation.

- Interior and Exterior Trim: Zinc die casting can handle the production of intricate door handles, mirror brackets, and emblems with high aesthetic value, decorative and strong corrosion resistance. Withstand harsh environments and marine bench salt fog corrossion.

- Electronic and Mechanical Parts: Zinc die casting components have excellent thermal and electrical conductivity. Suitabe for sensor housings, relay enclosures, and connectors in vehicles with advanced electronics.

- Safety Components: Zinc die castings were used for seatbelt components, airbag housings, and braking systems, offering reliability in critical safety applications. They are durable, castability and cost-efficiency.

- Cost-efficiency, durable : Zinc alloy die casting have been used widly for automotive interior and transimission components due to Zinc Die Casting Process Is Low Cost And high production efficiency.

Conclusion

In 2025, the automotive components zinc die casting market shows steady growth. Which is driven by the increasing of lightweight of fuel-efficient cars and Intelligence of electric vehicles production. More specific requirement of zinc die castings want more good solutions to meet. Custom die casting automotive component projects need more die casting manufacturers to finish. Because zin alloys material are easy to cast and durable, by zinc die casting process, they can be processed into high precision, diversity intricate geomotry in fast cast cycle. So more zinc die casting automotive components may be created and invest a mass production.