TangSheng Hardware Tech has a set of perfect quality control system. It handles raw material incoming inspection and outsourced processing incoming inspection. This ensures a steady products quality in mass production and reduces rework rates and material process lost cost and realize high efficiency production. Depends on different industrial specific quality level, some of finial products, exception of fitting the general quality standard. And also must meet their own industrial specific standard, and follow the industrial quality management system. This will provide high quality components to various sectors in the industry in high effeciency.

Raw Material Incoming And Outsourced Processing InComing Inspections

Raw Material Incoming Inspection

When raw material arrives at our factory, our incoming QC clerk inspect the incoming raw material. Firstly check if the appearance of them are broken, damaged and spoiled. Then refer to the testing report from material supplier. If neccessary, we can test these raw material properties with inspection instruments or process machines. Once their quality is ok, our QC clerk sign the label of QC Pass on the raw material. And receive them and put them on the designated areas of warehouse.

Metal Raw Material Incoming Inspection

- Check the appearance of raw material and if there is broken and damaged.

- Refer to the test report attatched with raw material, testing the material properties with inspection instruments or process machines.

- Make some samples to test the part functionality and properties.

- Sign QC Pass Label and stick on the metal raw material

Plastic Raw Material Incoming Inspection

- Check outpackage of plastic resin and if the package is broken and damaged, and ensure the weight of plastic raw material is enough weight.

- Refer to the test report with the lots of plastic resin, and melt partial of resin to inject custom plastic part and inspect the plastic part structure and properties.

- Sign QC Pass Label and stick on the package of plastic resin.

Outsourced Processing InComing Inspections

The lots of plated zinc die casting parts as outsourced processed incoming products, which will be inspected and tested. And pick up the defective parts from them , and execute all check 100% and ensure the lots of plated zinc die casting parts achieve high quality standard. Mainly Check the below key points.

- Check the appearance of each part, and find blank, porosity and peel.

- Using adhesive tape to test the electroplating material adhesion.

- Observe Thickness on the surface of each part, and if even and smooth.

- Check if there are any warpped and bended, and pick up them among them.

- Assemble the part with other revalated parts and test it fits.

Self Check On Production Line And ensure 100% All Check

In order to ensure that our processed parts are high quality, our quality management article regulates our operator should have a 100% all check to mass products during mass production. Once the defective part found, operator report management clerk or technician, and they will have a new adjustment and improvement, until the machine produces qualified parts. But also our operators can pick up the good quality and sort them, and ready for next post process.

All Check In Die Casting Process

Our operators are check each die casting part carefully when they remove the flash on the parting line and gate execess material. Whether the die casting part is wrapped,cold shut and scratches. The die casting part may be post processed, but the base die shape and structure and appearance is ensured. Our operators are often trained on quality control and inspecting the defective parts in production operation. This will handle the quality of each part and makes each product reach high quality standard. Here our operators execute IPQC management system. When operators remove execess material on surrounding of part, meanwhile they execute quality control. and sort the good die casting parts and put them into the designated box and deliver them to the next post process procedure.

All Check In Plastic Injection

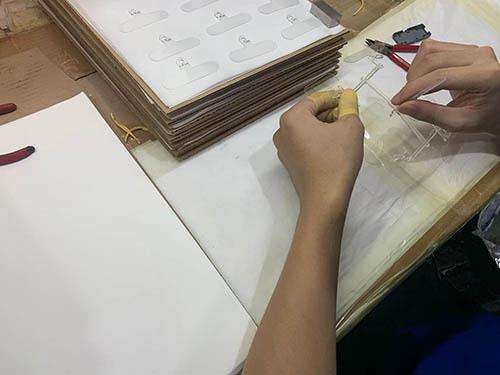

Worker should remove the flash on the parting line and gate execess material when the plastic part is injected. They check them and sort and put these deburred part on the designated panel and piled. Like these plastic injection part, operators check their defects and whether the part is shrankaged, wrapped and flow scratches on the surface. If the part is transparent, operators also check if there is impurify inside the part. Operator assist our plastitc injection technician to do best quality minitoring and ensure our each injection part reach high quality standard. Our production supervisor often train our operators to check the defetive plastic injection part and guide them to have a right avaluation standard and method. Our operators in plastic injection department have a good sort for these deburred plastic parts and classify them and sign the label and ready for the next post process.

All Check 100% In Post Process

The products that requires post process will accept all check 100% and keep high quality and being convenient to proceed surface finish options. Include deburring process and precision cnc machining process, operators should have an all check 100% to those processed products. Follow the quality inspection regulations for different processed parts.

All Check 100% Deburring Process

We remove the burrs on the part by hand and machine, operators can check each deburred part each time. If neccessary, the part can be processed again until meeting the standard of quality control. Because most of deburred parts can be delivered to outsource for better surface finish options, our worker should ensure the surface of these parts are smooth and even. The deburring methods are various , include of Mechanical Deburring, Vibratory Deburring,Manual Deburring,Cryogenic Deburring, Laser Deburring. We will do best deburring method and reach high efficiency quality. and execute all check 100%.

All Check 100% Cnc Machining Process

Whenever machining plastic and metal parts, we can inspect each one in process. Depends on the requirements of installment of the part, the part should be processed precisely by cnc machines and refer to machined prototypes and check each machined part and ensure a high quality standard of batch products. Of course we use some precision measure tools to ensure the dimension of the part. Our factory had some common precision inspection instruments , include of binary rule, Clipers, micrometers.

Finished Products Quality Control Inspection

The finished production inspection includes all components for the finished products smooth assembly, such as manual, components (plastic and metal parts) and protectional various package materials. Depends on the requirement of client and goods properties, our worker shoud package these finished products with reasonable package material. Our FQA clerk should audit the package of the finished product and open the box and inspect assembly components and follow the finished product inspection standard and execute the end package inspection before shipment.