Zinc die casting technology have developped for a long time. Along with optimization of zinc alloy material and die casting technology improvement, more and more complex geometries is cast by high precision high speed steel die and applied in more industries successfully, it has become a major manufacturing process. With the rise of newly industries, it requires continuous creation and improve and meet the requirement of the market in the future. Always Zinc die casting technology will have a wide market in the future.

Zinc Die Casting Technology Supports Minature Parts

The Advantages Of Zin Die Casting Technology

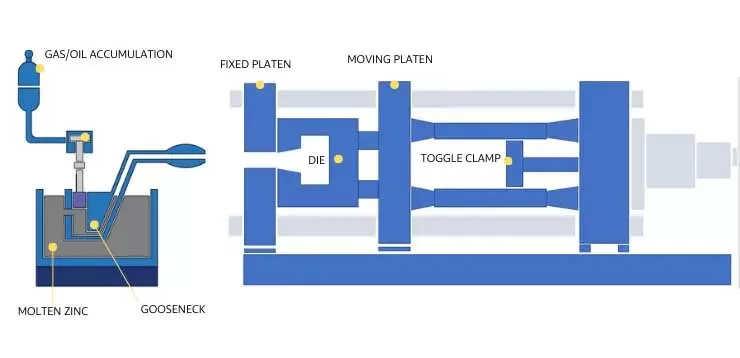

Zinc die casting technology is a high efficiency and precision manufacturing method. With precise high speed steel die, produce high quality mass products, at low process cost. Meanwhile process various complex geometries and used in many industries. At all the type of die casting technology supports the process of low melting points metal, such zinc, lead and tin etc. And ensure the exellent dimensional accuracy and fine surface finish. The blew key points.

- High Precision & Tight Tolerances: The technology supports the process of miniature part, which require high precision and tight tolerances. With high precision high speed steel die, cast intended metal part.

- Excellent Surface Finish: The high precision high speed steel die, includes of two halves,which is the core and cavity of the die. By cnc machining center and EDM, polishing the surface of the core, and maitain excellent surface finish.

- High Production Speed & Efficiency: Zin die casting technology keep a fast cast cycle due to zinc alloy materials properties, which are low melting point metal, require low temperatures to melt zinc metal ingot and cast high quality zinc die castings in high efficiency.

- Cost-Effective for Large Runs: Zin die casting process has high effective mass production and cost-effective rate. In high volume process, it is cost effective due to low energy consumption and fast cast cycle.

- Excellent Corrosion Resistance: Zinc alloys are complate metal materials, and contain the metal element of corrosion resistance , magnesium. So the technology supports producing exellent corrosion resistance cast parts.

- Eco-Friendly & Recyclable: Zinc is 100% recyclable without losing quality, supporting sustainable manufacturing. So zin die casting technology serves zinc alloy recycled and reusage, maintain zinc alloy eco-friendly and recyclable.

What Is Market Applications For Zinc Die Casting Technology ?

Using zinc die casting technology widely across many industires due to its precision, durability, cost-effectiveness. Focus on the miniature size accurate dimensions metal parts, and have a huge market needs. With the rise of internet and 5G technology, Signal tower and inferstructure requires the miniature parts zinc die casting. However the technology support the hot chamber die casting process, and offer mass production in high efficiency. and produce more industrial appplication parts.

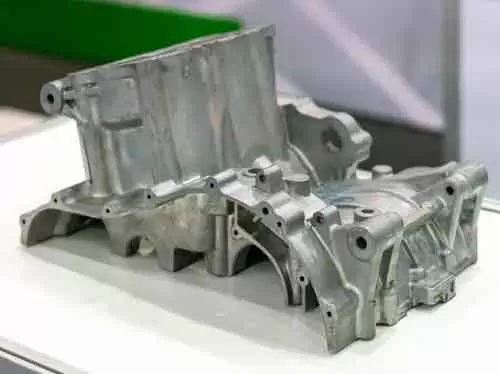

- Automotive Industry: such as safety belt system, headlight housing, interior and exterior lock tool and button cover and transmission housings.

- Electronics & Electrical Components: Smart earphone enclosures, connector and terminals and heat sink and EMI shielding housing.

- Consumer Goods & Appliances: Gifts, appliance components(handle and display panel).

- Industrial Machinery & Tools: Precision mechanical parts, gears and housings.

- Medical Devices & Equipment: Miniature size precision die casting housings and case for Diagnostic equipment.

- Telecommunications: Antenna components and EIM shielding.

- Aerospace & Defense: Lightweight metal component for aerospace and defense.

The Future Market For Zinc Die Casting Technology

Zinc die casting technology creates cost-effective and durable metal products, drive zinc die casting manufacturing to become a major production process. With the largement of industrial applications, its the future market is justly changable and adjustable and meet the requirement of industrial applications. As miniature parts, they need more high tolerance dimension and complex designed structure. The Future Market For Zinc Die Casting Technology faces creative challenges and deeply improvements.

Changes Industrial Market

Zinc die casting technology have been used in traditional industries for a long history. Now its application is just changing into some newly industries, such as EV manufaturing, Inferstructure of internet of things and Smart devices housings and enclosures. These industries need high precision and complex geometries metal parts. Aditionally, various custom and personlized designed parts also develop the new blue sea market. To offer high quality zinc die castings to these newly industries, industrial audit standard is released and let die casting manufacturers to follow the newly industrial product application standard. Undoubtedly, The huge requirement of zinc die castings is Automotive, 5G and Internet of things deployment. but more high audit standard will be released for filtering mass zinc die castings in market. The enterprise should comply with industrial requirement standard to produce suitable for industrial applications. So changes in dustrial Market makes die casting gain more indjustrial audit standard for zinc die castings.

Flexible Geometries And Structure Design

With advanced 3d design soft CAD software, engineers can flexible design geometries and structure. Depends on the designed 3d model, engineers can design high precision casting die and manufacture the die with cnc machining center and EDM. By zinc die casting technology, factory can produce plenty of high quality zinc die castings. Also it supports the process of miniature part zinc die casting, which are housing and enclouse of electronic mould. Its design follow electronic mould shape, and its structure is strength and steady and ensure the mould can run safety.