In modern information era, Data storage and transportation will spread to eveywhere peope live and work. People need more data storage devices to store data. USB flash disk is our common data storage tool. To seek for good appearance usb flash disk, the branded business man chooses metal housing wrapping the electronic core moudle. Either the outside housing can close the electronic curcuit or protect the electronic core moudle well. Zinc die castng housing is best choice for USB flash disk due to zinc alloy specific properties and zinc die casting high precision. So zinc die casting housings for USB flash disk have become so popular in Die casting factory.

Die Design For USB Flash Disk Housing

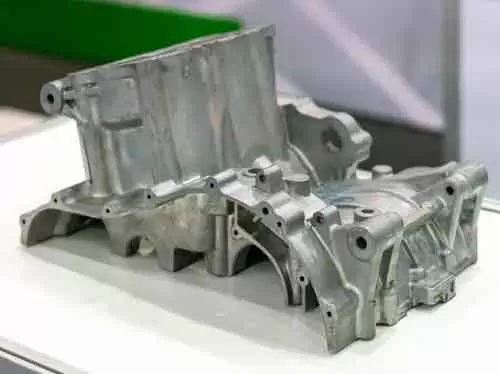

To aim to high effectiveness mass production for usb flash disk housings, we should design high quality casting die for them, considering of these constraint factors for design of the mold, our engineers carefully design multi-functions casting die, Especially zinc die casting mass production, which needs of the cavity of the die with tight tolerance dimensions, the core of the die with supperior suface finish, proper gate and vent channels and ejector control system.

To be sure that the specific die has a longer life time, our mold technician deliver the mold to quenching and gain an ideal result. In designing the die, our engineers and technician always have more meticulous considerations for cost-efficiency and lead time. We promise every client and business partner that we try our best to creat the best die casting solution for high performance casting die.

Zinc Alloys Choice For USB Flash Disk Housings

The below zinc alloys are common castable material, depend on different mechanical properties, manufacturer choose the blew zinc alloys to cast functional and practical usb flash disk enclosures.

Zamak Serial

- Zamak 2 With higher copper content, and used in specific applications. And has higher hardness and more wear.

- Zamak 3 most popular choice, its feature is excellent fluidity, meets the requirement of thin-wall usb flash disk housing. Good dimensional steady and high ductility, and realize various texture surface finish and eay plated.

- Zamak 5 Enhanced Strength, and has higher tensile strength and hardness, contain tiny Magnesium element, and enhances the zinc alloy hardness. Maintain good castability.

- Zamak 7 With superior corrosion resistance, and good mechanical properties , and also higher cost than Zamak 3 and 5.

ZA Serial

- ZA-8 High-Performance, Highest creep resistance, good corrosion resistance, and suitable for thin-walled housings and enclosures. keep an accurate dimensions.

- ZA-12 : higher aluminum content contained, and suitable for bigger size USB flash disk housing.

- ZA-27: Offering exceptional mechanical properties, smaller density and Good thermal conductivity.

High Precision Mass Production For USB Flash Disk Housings In Zinc Die Casting Manufacturing

Precision Cast Die Process

Usb flash disk housings need a tight tolerance in dimensions so that fits USB socket justly. So the dimesion of the usb flash disk housing should match with general USB socket. And gain an accurate dimension. Precision extention of zinc casting die will decide the accuracy of the dimension of the usb flash disk housing. Our engineering team can collabrate with the client and design and process precision cast die. From product conception to real sample, with professional work-experience and design principle, our engineers can design and produce high performance zinc cast die.

High Effective Mass Production

Zinc alloys are low melting point metal material, these zinc alloys can be molten at lower temperature and under high pressure, and injected into the precision cast die and shape the part and eject it out from the die. The process cycle is fast and cast a part in seconds.These molten zinc have good fluidity and ductility, and just makes thin wall USB flash disk housing. In high volume Production, zinc die casting process is high effective and cost- efficiency.

Minimizing Secondary Processes For Zinc Die Castings

As-cast zinc parts, which need minimize secondary processes, such as deburring process, cnc machining and polishing, ready for futher surface finishes. Sometimes, CNC machining makes more thinner wall usb flash disk housings and positon more accurate dimensions. Polishing the surface of zinc die casting usb flash disk housing makes its suface smooth and even and removing residue and grease and create a good bond to electroplating material.

Various Surface Finishes For Zinc Die Castings

Zinc die castings suface finishes, such as powder-coated, electroplated, printed and electrophoresis. Depends on the specific requirement from client, we will have best surface finish option to treat these zinc die castings. Sometime client require mark their brand and logo on the surface of zinc die casting parts and promote their brand and enlage their sale scale. We can mark colorful laser engrave pattern on the surface of the cast parts. as called Laser Marking On Zinc Die Castings.

Why Choose TangSheng Hardware Technology

Who We Serve

Professional Services and High Quality

High Quality Parts

With sophisticated engineering design team, automated streamline and strict international quality system management rules . And insist on conducting strict quality contol on each process phrase. Maintain 100% inspection.

Engineering Team Support

Well-experienced Engineering team supports die casting part design and high quality mass production. Ensuring cost-efficiency in high volume. With consistent high quality product output.

Meet Various Requirements

Meet various requirements of die casting parts in many industries, such as automotive, commnunicatioin, electronic consumer, medical and heavy industrial equipment.