Best Aluminum die casting manufacturer always uses MAGMAsoft simulation to test the designed die casting process before physical production. When engineers test the designed die casting process with MAGMASOFT, they can find some defects ahead, at once improving and optimizing the defective die casting process, creates the best aluminum die casting process and better realizes mass production in high efficiency. So MAGMASOFT Simulation optimizes aluminum die casting design process ahead. Its Advantages reflect the below key points, saving the man hours, energy concumption during the original die casting process, castable prototyping material waste and the cost of engineers improvement and adjustment.

Why Use MAGMASOFT Simulation ?

Challenges are inevitably arised in the manufacturing process when there are the divergence between the desired design of client and real physical operation. Some conflicts generate in real operation, lead to troubles minifest in mass production.This makes us have an dispensable adjustment and modification for former aluminum die casting process. Now, advanced predictive computerial plugin can find some trouble and leakage holes in alumiunm die casting process design in advance, and improves and optimizes the die casting process timely. Best aluminum die casting manufacturer always uses magmasoft simulation to test the designed die casting process before physical production. Save more propotyping die material,man hours and energy consumption in aluminum die casting process.

We are all known that there is much gas porosity on the surface of aluminum die casting part when they are cast. The engineers take some ideas to implement Aluminum Casting Impregnation to create a fine suface finish. By MAGMASOFT Simulation test, we can deploy the aluminum die casting part suface finish in advance, and test and predict the effect of impregnation, and optimize and adjust some design and achieve the best result.

TangSheng Hardware Technology engineers have been using MAGMAsoft for more than 16 years. Our years of experience using simulations and numerous projects make us offer high quality aluminum die casting parts in cost-effective mass production.

Predicts,Improves And Optimizes Die Casting Process

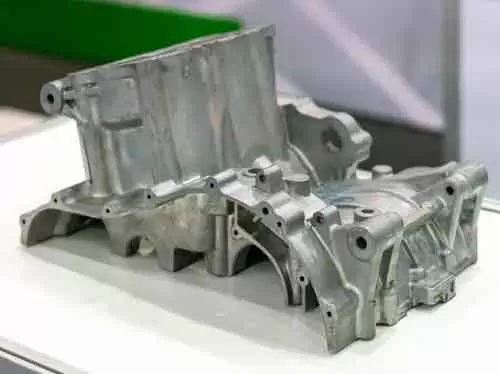

From the start, our engineers want to design perfect aluminum die casting, but unfortunately, there are times when the original casting design is inherently prone such as gas porosity, cold shut and shrankag defects. In order to prevent these defects or reduce the defective rate, our engineers use MAGMAsoft simulation to test their original die casting design and optimize and improve the die casting better.

With the magmasoft process simulation, die casting manufacturer can optimize filling chracteristic, temperature control and machine parameters and further improves the original aluminum die casting process and offer the better die casting parts. Also the soft can save more man hours, prototyping material waste and engergy consumption.

At Lower Cost, Perfect Die Casting Part Offered

Higher costly prototyping process, tooling process and highly man hours should be contributed to the first trial of aluminum die casting process. When the magnasoft process simulation is used after the original die casting design finishes, engineers can predict in advance that some troubles in the designed die casting, and at once take some improvement methods to perfect the design functions. Doing this way, without the first trial of the die casting process, we will improve and optimize the die casting process quickly and achieve a perfect die casting process, and produce perfect aluminum die casting parts successfully.

Learn More About Alloy Material, Optimize And Fills The Flow Fully Into The Die

How do we cast the perfect aluminum die casting part with the specific aluminum alloy ? Through The magmasoft simulation testing, depends on the flow charter, we can lean more about the specific aluminum alloy, and try our best to optimize the molten aluminum flow, improve Gating & Feeding Systems and make it fill into the die fully. Meanwhile iteratively improve runner, sprue, and riser designs for yield improvement.

Futher Gloss The Core Of The Die , Improve The Surface Of The Die Casting Part

Aluminum die casting part needs a fine surface finish. With the magmasoft simulation, we found that the core of die require a glossy surface to cast a fine suface finish die casting part.But unfortunately we can’t the glossy surface, and should use advanced testing soft, and test whether the core of the ide is smooth enough and make a fine surface finish effection.