Metal Die casting have common two types of die casting processes, which are cold chamber and hot chamber die casting processes. In modern industrial Manufacuring, These two types of main die casting is account for 80% overall die casting manufacturing industry. Cold chamber die casting is suitable for higher melting point metal alloys, such as aluminum, copper, iron and stainless steel. It is high energy consumption industrial manufacturing process, Comparison to hot chamber die casting, which is suitable for lower melting points metal. Today, I will have an outline of cold chamber die casting: material, process and advantages.

What Is Cold Chamber Die Casting ?

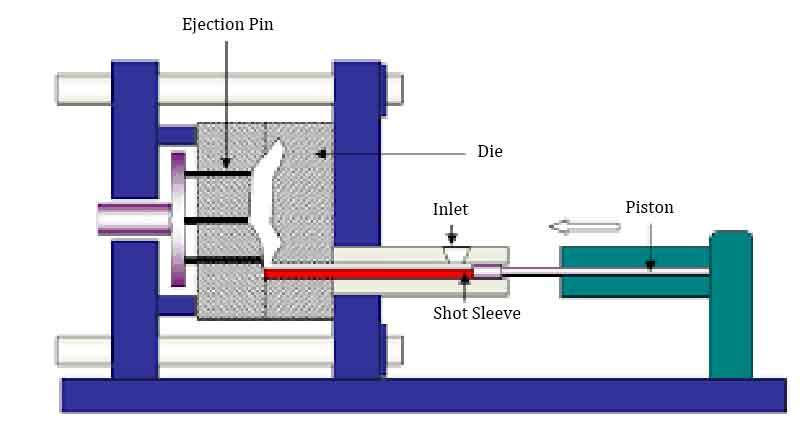

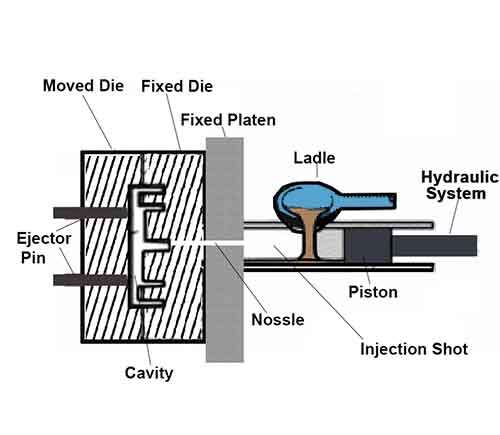

Cold chamber die casting is a process in which the melton metal furnace is seperated from the machine completely, and require ladling the molten metal and feeding it into the shot and pushing the molten metal into the die with hydraulic piston and fill the die fully under high pressure, cooled and solidified and form as-cast part. This process is favor of higher melting points metal, such as aluminum, copper, stainless steel alloys.

The cold chambe die casting is different from hot chamber die casting. Its separated furnace maintain the higher temperature molten metal and requires delivering the molten metal to feeding shot and then injecting metal into the die and form the cast part. Injection system is different from hot chamber die casting, as the blew issues.

- Separated Furnace (For high melting points metal melting pool)

- Gas Accumulation System

- Injection Shot Mechanism

- Nossle

- Piston

- Dies

- Ejector Pins

The process firstly requires melting metal in separated furnace,overflow the impurities within the molten metal, and maintain steady temperature and good fluidity metal in reservoir. Then ladling the molten metal from the reservoir, and pouring into the injection shot, die casting machine add pressure with gas accumulation and push the piston driving the melton metal into the pre-heated die, inside vaccum die, the molten metal fill the core and cavity of the die fully. And Cools the die and solidifies metal die casting part. The die opens, and eject the cast part with ejecotr pins.

The cold chamber die casting is favor of higher melt point metal, and have a fast injection, longer cooling time and excellent surface finishing. But its defective rates is higher, comparison to hot chamber die casting.

Material Is For Cold Chamber Die Casting

These high melting points metals need higher temperature to melt, inject into the intended shape and functional components. Depends on their own features, these metals can be processed and used for important fields.

| Metal Alloy Items | Material Examples | Characters | Applications |

|---|---|---|---|

| Aluminum Alloys | A380, A360 and ADC12 | Lightweight, Excellent corrosion resistance and high thermal & electrical conductivity | Aerospace, Automotive, Industrial equiment industries |

| Copper Alloys | Brass and Bronze | Excellent thermal & electrical conductivity, High corrosion resistance and high hardness | Electrical components, tube fitting, valve and craft and gift. |

| Iron | Iron | High density, Strong corrosion resistance and Durability | Heavy machine main frame, chassis and countweight parts. |

| Stainless Steel | SUS 201, SUS202, SUS 402, SUS 403 | High hardness, excelent surface finish and high corrosion resistance | Heavy machinery components, tube fittings and jewellry. |

Cold Chamber Die Casting Process Guide

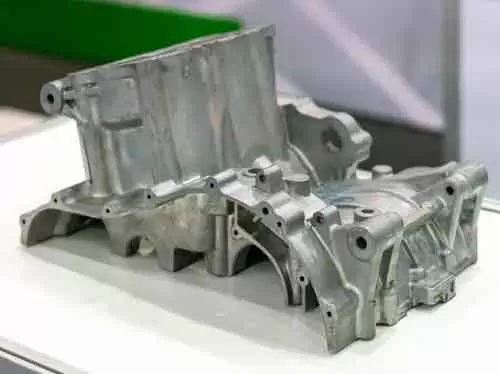

Some large size cast parts required for heavy industrial equipment components and countweight, die casting manufacturers often produce these heay weight die casting components with cold chamber die casting machine. The cold chamber die casting process runs the below steps one by one.

Step 1: Mold Preparation

- The precise mold & die has a higher intial fabrication cost, and ensure a longer life time of it, and preheated and avoid cold shut and flow trace of cast part occurred.

- Die Release agent is sprayed after each cast cycle finished, and ensure the cast part ejected smoothly each time. Keep the halves of the mold is alignment with each other, and makes ejector pins eject the cast part from the core of the mold.

#Step 2: Melting & Pouring

- Melting these high melting points metal with high volume heat energy, and overflow the impurities within the metal, maintain the steady temperature molten metal in reservior. And have a sufficient preparation for pouring the molten metal.

- When molten metal is manually or automatically ladled, and poured into the cold chamber shot. This is mechanical action, replace labor operation, reduce some accidents for scald.

Step 3: Injection

- The hydraulic or mechanical plunger forces the metal into the die cavity at high pressure, and fill the metal into the die fully quickly. These high melting points metal have a good fluidity, and forms high accuracy dimensions and fine surface finishing under high pressure.

- Pressure ensures strong integrated structure and fine surface of cast part, and minimizing post-process operations.

#Step 4: Cooling & Ejection

- The metal cools and solidifies inside the die when the metal is filled into the cavity of the die fully, The cold die casting machine start water cooling system, cools the die, makes the metal inside the die solidifies in shorter time.

- The die opens, and ejector pins push out the casting part, and a cast cycle finished. The die close, proceed the next cast cycle.

Step 5: Trimming & Finishing

- As-cast part require some post-processes for deburring. Depends on the specific requirements of process, the cast part may be machined.

- Secondary operations (machining, surface treatment) may be applied. Such as polishing, grinding, bead blastering and other trimming operations.

Advantages For Cold Chamber Die Casting

Suitable for Higher Melting Points Metal Alloys

The prcoess is suitable for high melting point metal alloys, its precise die and excellent metal fluidity creates tight tolerance dimensional cast part under high pressure. And is ideal for these metals , such as aluminum, copper, iron and stainless steel.

Separated Melting Furnace

To prevent the damage of the die casting machines from high temperature for high melting points metal, separeated melting furnace is set. Using High heat energy to melt the high melting points metal, and overflow the impurities within the metal alloy. And maintain the steady temperature purified molten metal in reservior for pouring.

High Precision And Excellent Surface Finish

The precise steel die and excellent fluidity molten metal creates the metal part with high precision and excellent surface finish under high pressure. And also ensure integrated structural cast part, maintain good mechanical properties.

Cost-effective For Medium Size Parts In Mass Production

Medium size parts require shorter time to cool and solidify, so mass production for medium size parts is cost-effective, since each cast cycle is faser than large size part.

Flexible Geometries And Thin Walled Parts

The design for cast die is flexible, engineers design some specific part appearance and structure for complex functions of cast part. Like added boss, fillet and thin walled factors. For cold chamber die casting design, which is flexible, diverstiy and complex.