Miniature part zinc die casting means small sizes zinc die casting part, which has tight tolerance dimensions, flexible apperance and fine surface finishing. With precision high speed steel die, high volume consistent qualified precision miniature parts production runs in high efficiency in zinc die casting process. The cast part process cost is lower due to metal properties of zinc alloy, which is lower melting point metal, and have less energy consumption and shorter cycle time. Comparison to other higher melting points metal alloy, which needs more energy consumption and longer cycle time, like aluminum, copper, iron and stainless steel. With the largement of miniature parts die casting, zinc die casting process have become popular and imminent in industrial manufacturing. For die casting manufacturer, who need learn more about overview of miniature parts zinc die casting.

Advantages For Miniature Part Zinc Die Casting

With the rise of some newly industries, miniature parts zinc die casting have been approved and defined, and widely used for automotive, communication and consumer electronic industries. It advantages reflects clearly as the below main points.

- Dimensional accuracy and complex design: Achieves tight tolerances and intricate designs.

- Material properties: Zinc alloys offer superior strength, excellent ductility,corrosion resistance, and good wear resistance.

- Cost-effectiveness: High production efficiency, less energy consumption and cutting edge die casting machine lower its production cost.

- A big volume production : Implement a big volume production, consistent high qualified products and repetitive manufacturing.

- Smoother surface finish: precision zinc casting die and premium fluidity molten zinc creates smoother surface finish.

- Recyled and Sustainability: Zinc alloys are 100% recyled, and reduce waste material , and remelt useless zinc die castings and cast newly die castings with diversity geometries. Zinc alloys are sustainable and good eco-friendly.

Miniature Part Zinc Die Casting Production Step By Step

Ts technology is specializing for manufacturing zinc die casting parts to meet various requirements. Client provide their drawing and design plan to their supplier, hand to their supplier to design the product that they desired. It contains the design of custom product model and creating precisoin molds or dies. and then produce high-quality custom die casting components. Miniature part zinc die casting production steps as the following.

Step 1 Precise Cast Die Design And Manufacturing

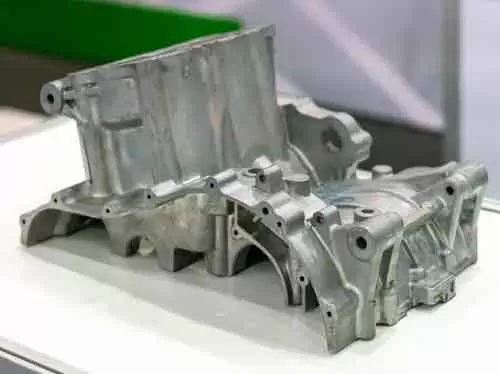

Engineers design precision mold with cutting-edge design software, such CAD, Proe and Solidworks. Then they have a predictable testing with die casting simulation tool on computer, and optimize and improve the design of mold until the design of mold is confirmed. The precision molds are made from high-grade steel and using advanced machining methods like CNC machining and EDM to ensure durability and accuracy.

Step 2 The Right Material Options

Among various zinc alloys materials, the manufacturers can choose the best alloy material to make zinc die casting components for qualified requirements.

Step 3 Arranging Die Casting Process

Depends on the different alloy metal material, operators choose the appropriate furnace to melt the castable metal alloy, and keep the steady temperature and filter impurity inside the melton alloy material and keep the good fluidity of the alloy material and take a preparation for die casting process. The hot chamber die casting machine inject the molten zinc into the pre-heated die under high pressure, and cools and solidifies and form the precision miniature cast part.

Step 4 Post Process And Diversity Surface Finishes

These custom die cast parts can be finished with various surface finishes, afterwards, they need minimal post-process. Through additional treatments like polishing, plating, or painting to meet appeal decoration or functional needs.

Miniature Part Zinc Die Casting Applications

Automotive Industry

Many miniature zinc die-cast components have been used in large scale in automotive industry . However these zinc die casting components designs require high precision, strong corrosion resistance and an accurate dimension. Commonly they have these automotive components as the follow.

- Interior and Exterior Components: handles, car logos, decoration trims and switch covers, which require wear to resist, and durable, and high corrosion resistance.

- Electronics housing: Zinc’s EMI shielding properties make it ideal for sensor and control unit housing and enclosure. And protect the electronic control system runs smoothly. The electronics housing is suitable for some small sizes zin die casting components with precision intented design geometries and strong corrosion resistance.

- Fuel Tube Systems Components: These components are miniature, and used for fuel tube of cars, like fuel tube fittings, valves and fuel filter, which withstand acid corrosion from fuel for a long time.

- Ignition lock and door lock components: These miniature part needs personalized design for some sport cars, zinc alloy allows for some specific structural lock core and ensure the lock is security and flexible structural design.

Consumer Electronics

Miniature zinc die-cast parts in the consumer electronics industry have electricity conductivity and thermal management, effective protective purpose. Particularly for:

- Device frames and housings: Exiquist frames for smartphones, laptops, which is evenly wearable, and is beneficial due to zinc’s castability and excellent mechanical properties.

- Connectors and ports: Durable and compact zinc castings require good electrical connectivity and long product lifespans. Zin metal has a good electrical conductivity. keep electronic curcuit connect consistently.

- Smart Wearable Device Enclsoures: Earphones enclosures, which need freely and flexible ergonormics design. zinc alloy allows optimal intricate and comfortable appearance design and supperior surface finishing.

Communication and Internet

The rapid expansion of communication networks has created big business oppotunity for miniature zinc die-cast components. The follow sectors in Communication and Internet require more miniature zinc die castings. we provide the below specific zinc cast parts.

- Network infrastructure: Miniature connectors, enclosures, and adapters in networking equipment. To build advanced Internet 5G for LoT projects, Many network infrastructure equipment require more miniature zinc die castings. With which build communication internet to finish the fundamental equipments assembly.

- Signal shielding: Zinc’s electromagnetic inference (EMI) shielding components protect sensitive electronic components in wireless devices. To avoid these control system unit to interfect other moudle system running. These signal shielding also protect core electric components well.

- Antennas and hardware: Durable, lightweight and miniature zinc die casting parts ensure signal clarity and structural integrity. The zin metal is not easy to rust and oxided, and withstand worse weather and environment weather. Still keep good signal transmission and electricity conductivity.

Healthcare and Medical Devices

Miniature zinc die casting in the healthcare industry, with its flexible design and precision process advantages and zinc material unique metal properties, They can be used for medical device components.

- Precision Medical Instruments Cases and Housings: Such as surgical tools and diagnostic devices require small, intricately designed parts. Also having a fine surface finish. Zinc alloy allows for producing miniature cast parts in high efficiency.

- Device components: Zinc die casings is suitabel for these equipment like blood pressure monitors and inhalers.

- Wearable medical technology: Miniature zinc die casting lightweight ergonomic enclosures for health-monitoring devices. Such as magnetic therapy watch, hearing aid and stethoscope.

Aerospace and Defense

In aerospace and defense field, we need using miniature zinc die castings to meet the below applications. Engineers require creating complex geometries and mutil-functionality metal cast parts. Meanwhile, these zinc die casting components may be applied on military defense field.

- Avionics components: Lightweight housings for navigation and communication equipment, like central console and safety systems on plance. ZA alloy allows for more lightweight flexible cast parts in aerospace industry.

- Weapon systems: Some small, intricate zinc die casting parts in firearms, targeting systems, and other military devices require more intricate design and precision deep process.

- Maintenance tools: Some emergancy for Compact tools are zinc die castings on bus and plance. Such hand brenches.emergancy hammer.

Industrial and Machinery Equipment

zinc die casting’s in Industrial applications benefits from its ability to produce precision and custom components, Some miniature components zinc die casting can instead of other heavy materal compoents which have poor corrosion resistance and heavy weight. and enhance component high performance.

- Precision gears and pulleys: Used in machinery for smooth operation and efficiency.

- Control knobs and levers: Zinc material provides durability for parts exposed to frequent use. Intented design geometries finished completely.

- Valve bodies and fittings: Compact zinc die-cast components enable reliable fluid control. These miniature zinc die casting fittings can be assembled with other metal pipes and valves bodies smoothly.

Jewelry and Fashion Accessories

The felxible design of zinc die casting is also suitable for fashion accessories and jewelry. And meet an aesthetic appeal and miniature sizes decorations.

- Custom jewelry: Miniature zinc die castings are intricate, lightweight designs with detailed finishes and unique appearance. And can coat more shinier color on the surface of these castings and present luxury and classic stylish.

- Accessories: Buckles, clasps, and ornamental parts may finish complex shapes. These zinc cast parts are small size and exquisit.

- Decorative fittings: Used in high-end apparel, bags, and footwear. We need more custom design and precision big volume production. Even though secondary process, like plated chrome and present more luxury appearance.

Conclusion

Miniature Part Zinc Die Casting’s applications range is still increasing. From automotive and healthcare to consumer electronics and jewelry, miniature zinc die casting have been used in many industries due to its unparalleled precision and versatility. Zinc die casting process allows producing durable and complex miniature cast parts at large scale. This makes it an essential technology for modern manufacturing. As demand for high-quality miniature components rises, Zinc die casting technique should have a further creative idea. Consistently create more custom die casting components to meet more requirements in various industries.