TangSheng Hardware Casting Technology(called as Ts Casting Technology simplely ) is one of synthetic industrial manufacturers, who is specializing for metal die casting and plastic injection molding. Arrange post processess for these injection and cast parts,such as parts deburrings, polishing, grinding,drilling and tapping etc. And employing assembly and testing for finished products until packaging them for lead time shipment. This company had introduced advanced process machines, automatic production lines, follows international quality management system IATF 16949 2016 rules, and ensure deliver high performance finished products in high efficiency in lead time. This reflects Ts casting technology comprehensive capabilities.

Mold Design and Manufacturing

Design the mold , include of plastic injection mold and metal casting die, then manufacturing these mold by mold workshop.

Assembly and Testing parts

In where, all parts can be collected here, operator will install metal parts and plastic parts together and then finish the package.

Laser Engraving pattern

The factory has 5 sets of laser engraving machines, which can mark some patterns on these parts, whenever plastic parts or metal casting parts.

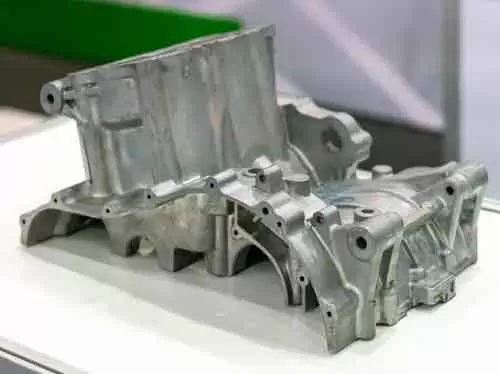

Die casting metal parts

Our own die casting metal parts production lines , process and produce metal die casting parts.

Plastic injection parts

Building own plastic injection parts streamlines, can manufacture many creative plastic injection parts

Casting part polishing

Polishing the surface of die casting parts well,smoother is for metal products, more easier to be electroplated

Die casting parts CNC Machining

die casting metal parts are processed by cnc machining, cutting, milling, lathing and trimming, aim to accurate dimensions.

Plastic injection parts Deburring

The excess material on the plastic injection parts are removed , and create fine surface finish, called as plastic injection part deburring

Rapid Prototyping Services

Proived plastic or metal rapid prototype before mass production at large scale. High efficieny and cost-effectiveness prototyping services

Mold &Die Design and Manufacturing

Our outstanding engineering team can design the mold & Die. They are always similar with 3d drawing soft, such as CAD , UG and Proe etc, and have full responsibility to finish any requirement raised by clients, whenever plastic injection mold or metal casting die .They will become your visual 3d model into a real sample within 15 days. If you need some real sample in one two day, we can arrange 3d printing prototype to you, and complete meet any demand from you.

- Design and manufacture mold & Die

- Similar with many 3d drawing softs, such as CAD, UG and Proe etc.

- Equipped with many CNC machining equipments and EDM machines.

- Well-skilled repairing the mold technical workers.

- Have some advanced grinding machines, milling machine and tapping machines.

- Outstanding engineers raising various reasonable solutions to client.

Synthesis Assembly and Testing

This is our synthesis assembly and tesing department. Where, operator will install metal parts and plastic parts together, testing finished product’s functions. In another one, package them here and send them to outsourcing factory. In this place, all products will be inspected again avoid there is any accident for quality defect.

- Assembly some die casting parts and plastic parts into finished products here.

- Packaging CNC machined, Milled, Lathering and polished parts and send to the outsourcing factory.

- Testing the finished products’ functions and check the parts and finished products’ quality again.

- Picking up the defective products and mark them and resend them to production line rework.

- Statistic data, recording the weight and account of parts and finished products.

Laser Engraving On Parts

We have many customer to need various pattern to be printed on the surface of products, laser engraving just resolve this problem, comparing to oil printing, that is resistant scratch, but also more durable. So we have 5 sets of laser engraving machine, which can mark some patterns on the surface of finished products are installed in our assembly and packaging department. Not only engraving the customer’s logo , but also marking some operation labels on the part.

- Engraving some logo from client on the surface of finished products.

- Engrave some marking labels on the the surface of the products.

- Be convenient and durable and resistant wore

- Promotion Laser engraving patterns for advertisement.

- Contrast color patterns on the surface of plastic or metal products.

Die Casting Metal Parts Manufacturing

With automatic die casting production lines, and can process and produce different metal die casting parts according to different requirements from client and business partners. With well-experienced technical person, completely meet individual customers’ special demands for die casting metal parts manufacturing

- Equipped with automatic die casting production lines

- Come with well-skilled operator and well-experienced technician

- Check the product quality themselves

- Deburring the die casting parts with advanced equipment

- Picking out original die casting parts and sorting deburred parts in respectively.

Plastic Injection Parts Manufacturing

Building plastic injection parts streamlines, produces many creative plastic custom parts. Such as soft plastic water proof mats and some plastic cover, which is made from TPU material. As IATF 16949 certified enterprise, so also provide and serve various kinds of custom plastic parts projects.

- Building plastic injection parts production lines.

- Equipped with automatic robot hands and decreasing scratch and fingerprint.

- Check each product quality themselves during injecting plastic parts.

- Deburring the plastic injection parts and sort out plastic parts

Die Casting Parts Polishing

In order to treat the surface of die casting parts well, we built our own metal parts polishing streamline. More smoother is for metal products, more easier to be electroplated. Something like that, they will become more appeal to audience’s eyeballs, so polishing workshop provides more shiny and smoother products so that be more convenient to hand to next procedure. Especially our zinc alloy car key case, which need a kind of noble and classic stylish. Its surface polishing requirement should be very smooth and shiny.

- We have a scale of metal die casting parts polishing streamline, main polishing parts include of zinc and aluminum alloy parts. Have various polishing methods for metal die casting parts, include of hemp wheel, cloth wheel , nylon wheel and steel wire wheel.

- Polishing metal parts according to business partners and clients, deep polishing and shallow polishing.

- Classify and mark those polished metal parts in respectively.

- Check each polished parts during polishing these metal die casting parts.

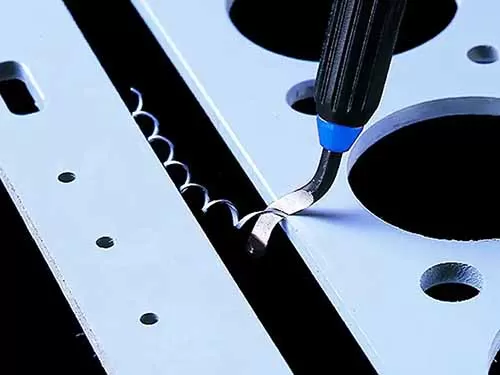

Die Castings CNC Machining

After the metal part is cast, these metal casting parts passed some initial cleaning processes. But untouched some rough area and hidden imperfection sharp edges on the metal parts can’t be removed and improved well. These metal parts require a further process for getting rid of sharp edges and improving imperfection areas. With CNC Machining, either achieve accurate dimensions or improve some specific functionalities of the cast part.

- CNC Machining Improves Imperfection Defects On Die Casting Parts

- CNC Machining Enhances Features of Die Castng Parts

- Positioning dimension and removing the sharp edges and execess

- Increasing Production Effection And Ensure High Quality Products

Plastic Injection Parts Deburring

These imperfection burr and redundant nozzle material should be removed. People are customized to calling: “PiFeng” in Chinese. So the process is Plastic parts deburring process. workers use hand tools like knives, scrapers, or abrasive pads to remove burrs manually. Sometimes the plastic parts are placed in a vibratory or tumbling machine that contains abrasive media, and do deburring.

- Worker use some manual tools to remove the edges and burrs on plastic parts

- With vibratory or tumbling machine, employing high frequency shakes and remove the easier falling burrs

- Some plastic part need thermal gun to burn and repair with high temperature the outline of it.

- Specific plastic injection parts can be trimmed by Ultrasonic, laser and chemical solutions.

Rapid Prototyping Services

Our professional rapid prototyping services provide high quality prototype for client in short time. Hereby there are two types. One method is designing die and molding tool, then produce a set of molding tool, and inject material into the mold and form ideal prototype. Another method is straightly printing prototype with 3d printing machine.

- Choose the right plastic material for 3d printer, often engineering plastic and ensure the rapid prototypes high quality

- Select advanced 3d printer, SLA (Stereolithography): Offers high-detail, smooth-surfaced prototypes, suitable for resin.

- Die casting prototypes, firstly design the casting die, then use the precise tooling steel die cast the rapid prototypes, and consistent modify and improve the casting die until the qualified samples made out.

- CNC machining can employ high-precision finishing, refining edges. Under computer numberious control, ensures that the dimensional accuracy of die-cast parts, ensuring they meet the desired specifications.

- Refer to the document requirements, and test the rapid prototype performance, and report the client, and deliver the rapid prototypes to the client in short time.