Common aluminum alloys like (6061, 7075),which are widely used for many components in aerospace and automotive industries. Since aluminum alloys have the properties of lightweight, excellent corrosion resistance, high strength,soft and easy to process. However, Zinc alloys(zamak 3,zamak 5) are higher weight(~6.6 g/cm³) than aluminum alloys(~2.7 g/cm³), which belong to lower melting point metal, high hardness, excellent mechinability. The both types of metal alloys have their own advantages and benefits, let us have a detail anylisis for them, Common Aluminum alloys Vs. Zamak Alloys.

Overview Of Common Aluminum Alloys

What are the disadvantages of 6061 Aluminum Alloy ?

- Lower Hardness & Poor Wear Resistance: Aluminum 6061 is softer than zamak 3, leading to wear in high-friction applications.

- Higher Production Cost Than Zamak 3 : Aluminum 6061 requires higher temperature to melt, and longer time for cooling, and higher defective rates, result in higher production cost.

- Not Suitable for Small Size Cast Parts Production: Higher thermal expansion can cause longer cooling time than zamak 3 during die casting process. result in longer cast cycle for small size part. The cost of mass production is still higher.

- Porosity in Castings, facing surface finishing challenges: Hydrogen absorption can cause voids, requiring vacuum casting or degassing. Or another Aluminum Casting Impregnation Reduce Shrink Porosity And Gas Porosity.

Applications Range Of 6061 Aluminum Alloy

6061 aluminum is most common aluminum alloy, used where a balance of strength, weight, and corrosion resistance is needed. It’s especially dominant in automotive, aerospace, marine, and general fabrication.

- Aerospace & Aviation: Aerospace components such as wing fittings, spacers & brackets and hydraulic body.

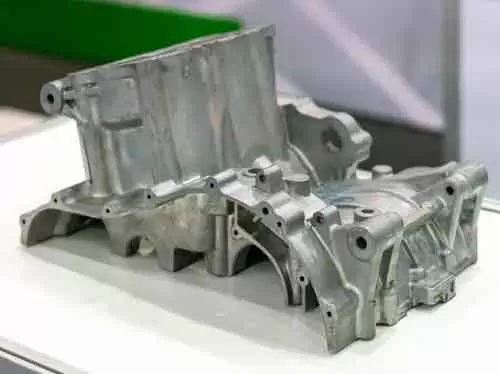

- Automotive Components: Frames and chassises, wheel and suspension components, heat exchanger and radiater, EV battery enclosures.

- Marine Applications: Boat hulls and decks, marine fittings and hardware.

- Construction And Archeticture: Door and window frames, decorative curtain, roofing & cladding.

- Consumer Goods & Electronic Enclosures: Sport bike frame, Camera body, smart phone and notebook casings.

- Industrial Applications: Piping and tubing fittings, robotic hand and arms, work tables and conveys system.

About Zamak Alloys

What are the disadvantages Of Zamak 3 ?

Zamak 3 is the most zinc alloy among the family of zinc alloys, which is used for various metal parts in many industries, such as automotive, appliance, industrial equipment, decoration and architecture, communication ect. but it also its own disadvantages.

- Heavy: 2.5x denser than aluminum, making it unsuitable for weight-sensitive applications.

- Limited High-Temperature Performance: Loses strength above ~120°C (250°F), not suitable for engine components or hot environments.

- Corrosion Resistance Requires Plating: Bare zinc in humid or salty environments requires equires chromate plating, powder coating, or nickel finishes for protection.

- Not Ideal for Large Parts: Higher density makes large zinc castings unwieldy and expensive (aluminum or magnesium are better for big components).

Applications Range Of Zamak 3 Alloy

Zamak 3 is the go-to alloy for high-volume, low-cost die-cast parts where strength is not critical. It dominates in consumer goods, automotive trim, and decorative hardware.

- Consumer Goods & Hardware: Zippers, buckles, and fasteners, with good hardness and good mechanical properties.

- Automotive & Electrical Components: Handle, seatbelt buckles, sensor enclosures, with high corrosion and wear resistance.

- Industrial & Machinery Parts: Bushings & bearings,excellent wear resistance, and high strength, withstand repetitive wear.

- Decorative & Architectural Uses: Furniture hardwares, lighting fixtures and lamp boxes, plumber fixtures,

- Electronics & Small Devices: Camera housing, wearable device enclosures and electromagnetic shielding cover.

Comparison For Aluminum 6061 And Zamak 3 Alloy Material

| Properties | Aluminum 6061 | Zamak 3 Alloy |

|---|---|---|

| Material Composition | Aluminum (~97%), Copper (Cu): 0.15-0.4%, Magnesium (Mg): 1.2–1.8%, Iron (Fe): ≤ 0.7%,Silicon (Si): 0.4-0.8%, Zinc (Zn): 0.25%, Chromium (Cr): 0.04-0.35% | Zn (~95.5%), Al (3.8–4.2%), Cu (<0.1%), Mg (0.02–0.05%) |

| Density | 2.7 g/cm³ (Lightweight) | 6.6 g/cm³ (Heavier) |

| Melting Points | ~600°C (Higher energy to cast) | ~380°C (Easy die casting) |

| Electrical Conductivity | 43% IACS (Good) | 27% IACS (Fair) |

| Machinability | Good (can be gummy) | Excellent (smooth cuts) |

| Castability | Poor | Excellent |

| Surface Finish | Tough, required additional post process | Natural smooth surface finishing |

| Applications | Aircraft and auto parts,Bicycle frames, Heat sinks,Marine components | Door handles and zippers,Electrical connectors,Toys/decorative items |

Tscasting Technology Provides Both Services: Aluminum And Zinc Die Casting Services

Tscasting technology is one of professional die casting factory, who has a team of engineering design and cutting-edge die casting machines, automatic production lines, well-skilled production operation worker, under the strict international quality system rules, and provide high quality metal die casting parts in high effective at cost-efficiency. We main provide aluminum and zinc die casting services.

Cold Chamber Die Casting Production For Aluminum 6061

Cold chamber die casting has been called as main industrial manufacturing method. It is ideal for higher melting points metal alloys, such as Aluminum, steel, copper, iron and stainless steel. die casting manufacturer can make custom die casting parts with specific function and aesthestical apperance.

Hot Chamber Die Casting Production For Zamak 3

We choose lower melting points metal alloys to make die casting components and ensure meeting client’s specific requirements. Such as zinc, magnesium, lead and tin alloys. As one professional metal die casting manufacturer, and possess advanced die casting machines and skilled-well technician and comprehensive management system to make various custom die casting components across many industries. This is hot chamber die casting production.