Aluminum die casting parts surface finishes have multi- methods on surface of casting parts. Depends on the applications and functions of die casting part, manufacturers can have different surface finish options. The target that they treat aluminum die casting surface finishing is extending the aluminum die casting part life time and enhancing its durability. So for aluminum die casting suface finishing options, Include of powder coating, paiting, polishing, plated,anodizing and textured and patterned finishing etc. These die casting parts surface finishes are decided by die casting surface finish design and client’s requirements.

Advantages For Die Casting Surface Finishing

To enhance life time, durability and appearance aesthetics of die casting components, our expert suggest that die casting suface finishing options is indispensable prcoess, include the below key surface finishes.

Corrosion & Wear Resistance Enhancements

Enhanced Component Appearance Aesthetics

Prolong The Life Time Of Aluminum Die Castings

Minimal Porosity & Defects

Enhanced Specific Functionalities

Common Aluminum Die Casting Surface Finishing Options

The Finishing Process Of Aluminum Die Casting is typically the appearance, texture, and smoothness of the surface of the cast part. Diversity surface finishes for die castings, which can be realized through secondary processes, which involve of polishing, power-coated, plated, anodized, painting, textured and patterned finishing etc. As The follow we list main options for die casting surface finishes.

Polishing

Polishing the die-cast part improves its suface smoothness and gloss . The die casting part polishing process is indispensable in treating the surface of metal casting parts. Such as Glossy, reflective surface, with a smooth texture. These polish finishes effection will be decided by the demand of next surface finish can be proceeded smoothly. Precision electric components, Decorative parts, consumer products like exquisite gift, automotive trim, and other components requiring a sleek appearance.

Plating

Die-cast parts electroplated have various finishes, such as chrome, nickel and zincto plated enhances corrosion resistance, wear resistance, or aesthetics. Aluminum die casting plating is special surface finishing option, these aluminum die castings should be have an impregnation process due to the feature of porosity on the suface of aluminum die castings. The resin impregnation seal the porosity of the surface of cast part, and create adhensive layer for electroplating material , better coating nickel, copper, gold and chrome on the surface of metal casting parts. These die casting surface finish material is expensive, but the effection is best. It can create a metallic look (e.g., chrome-plated). Consumer goods, automotive parts, and appliances components are all electroplated in real life.

Painting or Powder-Coating

Painting or powder coating finish means coating a protective or decorative layer of paint or polymer powder on the surface of the die-cast part. As Metal Casting Parts Coating, Sometimes it also need painted and powder-coated finish in order to prolong the life of the castings and decorative appearance. Powder coating offers a thin, durable protective finish. They are suitable for consumer products, outdoor equipment, and parts exposed to harsh environments.

Anodizing

Anodizing is an electrochemical process, which create the oxide layer on aluminum die-cast parts. Enhance corrosion resistance and allowing for coloring. Matte to semi-glossy, from natural silver to black, gold, or other custom colors. The matte may need shot blastered to treat contrast matte surface effection. These anodized aluminum die castings are used in Electronics, consumer products, automotive trim, and architectural components.

Texturing or Patterning

Some die-cast parts must carry with specific textured or patterned surface on it directly during the casting process. Text finish is very common surface finish, in term of making texured surface on the cavities of the mold. From sand-like textures to more intricate, decorative patterns or custom logos.

As-Cast Aluminum Die Casting General Process Guide

Our as-cast aluminum die casting components have a general process, follows our strict quality management system, and ensure high quality cast parts in cost-efficiency mass production, we will execute the below steps strictly.

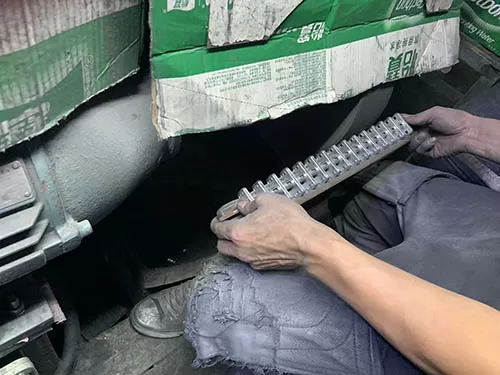

One Phase: Deburring:

These as-cast aluminum die castings carry with many burrs and sharp edges on it when they are cast. Firstly our workers can remove the burrs and excess material on the part with manual tools and abrasive machines, Some hidden burs on the cast part, using some special process methods, and removes all residues and excess material on the part.

Two Phase: Optimizing And Enhancing surface’s bond:

In general condition, our workers clean these deburred aluminum die casting components with water and acid. This gets rid of grease, oil and containments on surface of them so that bing convenient to painting and powder-coated processes. In some specific cases, these aluminum die casting components should be impregnated with the resin and metal zin and seal porosity on the surface of aluminum die casting fully and create an adhensive status for further plating process. This is strike process.

Three Phase: Finish Surface Finishing:

Our worker choose the right surface finishin option to coat the aluminum part, include of powder coating, paiting, polishing, plated,anodizing and textured and patterned finishing.