To reduce the overweight of Car or vehicle and ehance cost efficiency of fuel efficiency car and electricity power execss exhaustion of electric car, many other heavy duty automotive parts may be replaced by this kind lightweight products, which are automotive components aluminum die casting. These aluminum parts are either very light or good strength and strong corrosion resistance, and commonly used for automotive engine shell, wheel and battery chassis. They are large sizes and high precision, and have a good integrated structural properties. Their benefits also will show the follow aspects in the article.

Automotive Aluminum Die Casting Parts

- Lightweight

- Complex Geometries & Thin Walls

- Superior Surface Finish

- High Strength & Durability

- Corrosion & Heat Resistance

- Sustainability & Recyclability

Key Benefits of Automotive Components Aluminum Die Casting Applications

Lightweight and Reducing Overweight Of The Car and Vehicle

Aluminum is ~3x lighter than steel, and helps reducing vehicle weight. More aluminum die casting parts are installed on car and vehicle, and largely reduce the overweight of vehicle, Lighter fuel efficiency car can saving more fuels and lower CO₂ emissions, improve contaimination of air , and meet a strict requlation of the environment. The lighter electric car can start and speed up quickly, too.

Acceptable Complex Geometries & Thin Walls

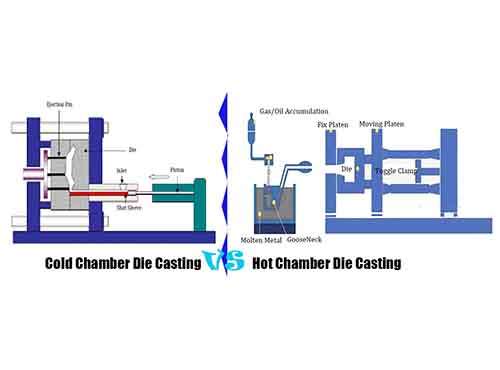

The Cold chamber die casting technique is suitable for aluminum die casting process. At same time, it also needs high precision high quality steel mold, under high pressure, injecting the molten aluminum alloy into the mold, and cools and solidifies into intended aluminum die casting part, and eject the part out from the mold. Since the molten aluminum alloy has a good ductility, and shape thin walls complex geometries. This just meet some specific requirements of automoble manufacturing.

Corrosion & Heat Resistance

Aluminum is natrual resist rust, touch the oxygen in the air, and generate Alumina, which cover on the surface of the aluminum part, create a protective film, and stop the other aluminum further Oxidation. The alumina layer has strong corrosion resistance. Aluminum has a nactive thermal conductivity, and can transfer the heat energy into the air and other substance quickly, and remain a steady temperature for automotive components.

Superior Surface Finish & Dimensional Accuracy

Automotive components aluminum die casting is processed by high precision casting die, so its suface is fine. Although a higher shrankage when the aluminum part is cooled, we can control some parameter tolerancy for die casting process and ensure dimensional accuracy of aluminum die casting part. Depends on the texture of surface of die cating part, our engineering team can offer diversity of superiou surface finish for aluminum die casting components.

Aluminum Casting Die Components are High Strength & Durability

The common aluminum alloys such as A380, ADC12, A383, offer excellent strength-to-weight ratio and high strength properties. Lightweight aluminum die casting parts can replace traditional heavy duty iron casting parts, and reduce the overweight of the car, makes fuel efficiency car and electric car more benefits . for engine blocks, transmission housings, and structural parts. These aluminum automotive parts are durable.

Sustainability & Recyclability

The aluminum die casting components are sustainable and recycled, similar with our zinc die casting parts in automotive industry. When these automotive components aluminum die casting have been used for a longer time, and lose their functions, they will be recyled, and reused, and melt them and reinject and fabricate the new die casting part or some defective parts reusage. So aluminum casting die components are sustainable and recycled.

Common Aluminum Alloys For Automotive Components Aluminum Die Casting

Refer to the below several types of aluminum alloys, we can have more knowledges about aluminum alloys, especially aluminum alloys for automotive components, and helps us choosing the right alloy to process high quality automotive aluminum die casting parts. Hereby show aluminum alloys parameters and mechanical properties.

Aluminum Alloys Parameter

| Aluminum Alloys | Composition | Properties | Applications |

|---|---|---|---|

| ADC12 | Si (10.5-12%), Cu (1.5-3.5%), Fe (<1.3%) | Excellent fluidity & castability | Transmission housings Engine brackets Sensor housings |

| A380 | Si (7.5-9.5%), Cu (3-4%), Fe (<1.3%) | High strength and hardness Good machinability and thermal conductivity | Engine blocks Cylinder heads Pump housings |

| A360 | Si (9-10%), Mg (0.4-0.6%), Fe (<1.3%) | Superior corrosion resistance Excellent pressure tightness (for leak-proof parts) Good ductility and impact resistance | Coolant system parts Fuel system components EV battery housings |

| A390 | Si (16-18%), Cu (4-5%), Mg (0.5-0.65%) | Extremely high hardness & wear resistance Good high-temperature performance Poor ductility (brittle) | Pistons Cylinder liners High-wear engine parts |

| ADC3 | Si (9-10%), Mg (0.3-0.6%), Fe (<0.6%) | Good weldability & elongation Better impact resistance than ADC12 | Structural chassis parts Suspension components |

Aluminum Alloys Mechanical Properties

| Alloy | Strength | Corrosion Resistance | Fluidity | Machinability | Best For |

|---|---|---|---|---|---|

| ADC12 (A383) | Medium | Good | Excellent | Good | Transmission cases, housings |

| A380 | High | Moderate | Very Good | Excellent | Engine blocks, pump housings |

| A360 | Medium | Excellent | Good | Moderate | Coolant parts, fuel systems |

| A390 | Very High | Low | Poor | Difficult | Pistons, high-wear parts |

| ADC3 (Al-Si-Mg) | Medium-High | Good | Good | Good | Structural parts, suspension |