With the growth of Electrical Vehicle and fuel car technology updates, zinc alloy die casting in the automotive industry become more challengable. Our transportation tool tends towards more and more intelligent, application of Internet to Things spread across our private cars and vehicles. These meteal components meet more cars and vehicles’ greater fuel efficiency and smart control. In future automotive industry market, lightweight and high strength small and medium size metal components required largely. They can be responsable for some specific mechanical parts and electric components in automotive sectors. And reduce overweight of car and vehicle, speed up its high performance. So automotive parts zinc die casting market size and share will be big.

What Are For Advantages Of Zinc Die Castings ?

Statistic shows that zinc alloys have some specific metal properties. So Zinc die casting can be used across vrious industries due to zinc unique metal properties. Zinc die casting components were more costly and durable, comparison to aluminum one. But also These zinc die castings have integrated structure and high strength-to-weight Ratio, Comparison too other heavy metal. The below key points have an enough proof.

High Strength-to-Weight Ratio And Flexiblity

Zinc alloys provide high strength and durability while keeping the weight of the components low. These parts can replace some heavy metal components in some specific field, enhancing machinery efficiency and performance. Meanwhile,zinc alloy die casting component’s appearance can also be changed at any time, only spending lower cost. It is flexible and convenient for personalized car and custom smart electric vehicle.

Strong Corrosion Resistance

Zinc die casting parts are exposed to harsh conditions, including moisture and marine bench. With excellent corrosion resistance. Especially some zinc alloy die casting components can withstand the salt moisture air on the bench of sea, avoid some fault the vehicle occurred.

Dimensional Precision

Zinc die casting produces precision components with tight tolerances and smooth surface finish. This due to high precision casting die, numerical control die casting machines and automatic production lines. Especially these small and medium sizes metal die castings require tight tolerance dimensions to assemble.

Cost-Effectiveness

Zinc die casting is highly economical, especially for high-volume production runs. The low melting points zinc metal can have a lower energy consumption, fast cycle time and less waste material during mass production in high volume. So zinc die casting creates lower cost metal cast part, compare to aluminum die casting, which require higher temperature to melt the metal. Zinc die casting is cost-effectiveness.

Applications Of Automotive Parts Zinc Die Casting

Automotive components made using zinc die casting due to zinc die casting parts are durable and cost-efficiency. Zinc alloys are easy to be cast and have strong mechanical structure properties, and meet the needs of automotive components functions,repetitive impacts and viberation. Some specific components provide attractive appeal appearance and corrosion resistance. the folowing items on automotive sectors have a sufficent proof.

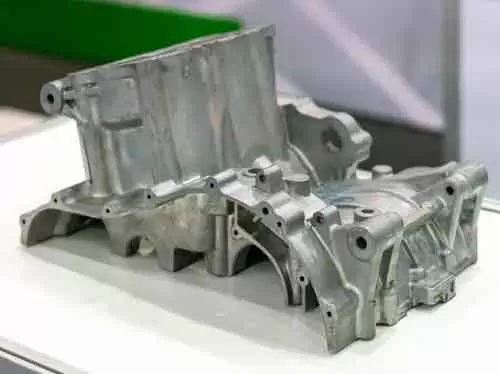

Transmission

These zinc die castings are strong yet durable housings that protect the transmission system while maintaining fuel efficiency. They are strongly corrosion resistance and solid, and have a longer life span. Follows transmission system space design, Various shaped zinc die casting transminssion housings are created in flexible.

Engine System

Zinc die cast engine covers offer protection for engine components. The zinc cover can have a good heat dissipation,can balance high temperature in engine components, maitain the engine have a lower temperature, work normally. The cover also endure the weight things repetitive impacts and effective protect the engine core well once any collision accident occurred.

Brackets and Supports

Structural components such as brackets that protect engine parts or electrical systems. These zinc die casting brakets and supports are solid and durable. The battery brackets for EV are made of zinc alloys, and either provide a good heat dissipation for battery reactors or fixing the battery on the support more steady.

Door Handles and Lock Mechanisms

Zinc alloys allow for precision casting of door handles and lock mechanisms, offers both aesthetic appeal and functionality. Zinc die casting design can create more attractive ignition starter setting for drivers and end-users and lock mechanisms. The automotive science is progressing, also zinc die casting innovation.

Fuel System Components

These Parts like fuel line fittings, fuel injectors, and pump housings. They require corrosion resistance and precise engineering. The common gas and fuel all produces acid and other corrosion during long term usage. The zinc die casting components can withstand fuel corrosion due to zinc strong corrosion resistance and rust resistance. Its precision and flexible appearance is suitable for automotive components market.

Electrical Components

Zinc has good electrical conductivity, is often used in connectors, terminals, and other parts within the vehicle’s electrical systems. Zinc’s heat-resistant properties allow it to be used for heat dissipation, avoid sensitive electronic components of the vehicle against high temperatures.

Security System Components

Common selt belt buckles, plug heads, airbags chassis and brake blades, which allows for zinc. From small size to medium size, zinc always creates high quality components, depends on ergonomic design, create appeal appearance and functional premium metal components.

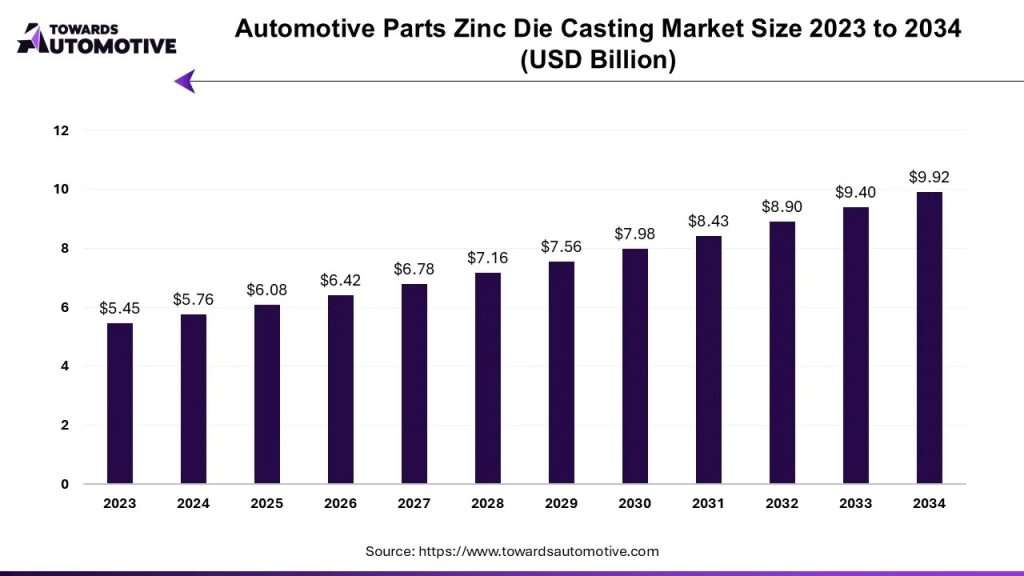

Automotive Parts Zinc Die casting Market Trend And Share

Automotive parts zinc die casting market is experiencing a steady growth, zinc diversity composition alloys will maintain consistent applications of high quality automotive components in some added fields. Especially, the rise of EV requires more precision metal parts to perfect its high performance. So automotive parts zinc die casting market requirement always keep stead growth.

Conclusion

Applications of zinc alloy die casting the automotive industry has become an indispensable. Since it offers numerious advantages such as precision, strength, and cost-effectiveness. With trends like lightweighting, electric vehicle production, and sustainability shaping the future of automotive manufacturing, zinc die casting will play an even larger role. Manufacturers who embrace the latest advancements in die casting technology, automation. Sustainable practices will be well-positioned to meet Automotive Zinc Die Casting Market Demand and beyond.