We Found that the automotive zinc die casting market had an obvious growth since 2010. Because the requirement of automotive industry was transfering towards lightweight components and ECO-friendly Trendy. As a typical metal material , Zinc alloys had been used across verious fields in modern industry. Zinc die casting stands out its several advantages,which is its excellent mechanical properties, corrosion resistance, and cost-effectiveness and sustainability. The process is regarded as ideal option for automotive components. When the market further expands, as electric vehicles (EVs) is account for near half market of automotive sale. With The creation of automation and advanced manufacturing technologies, automotive zinc die casting market will have a good development momentum.

Zinc Die Casting Applications In Automotive Industry

Zinc die casting had been used for various sectors in automtive industy with improvement and innovation of fuel-efficiency car and Electric vehicles. The process is either bringing cost-efficiency and eco-friendly or providing durable and high performance automotive component. From its utilizition functionalities, They will be devided into the below types in automotive application fields.

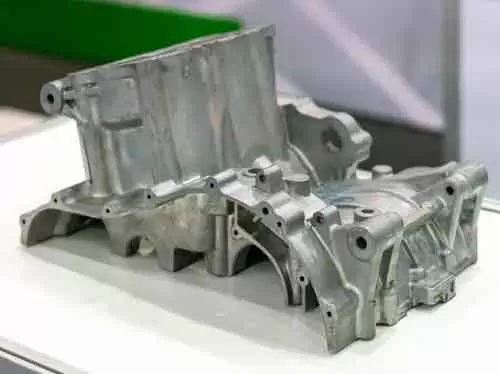

Transmission Housings

Zinc die casting provides the necessary strength and impact, which is essential for efficient vehicle performance. These zinc die casting components is lower cost and maintain same strong strength, integrated structure and excellent corrosion resistance,compare to aluminum die casting. This is beneficial to reduce overall price of a car when keeping vehicle high performance . So zinc die casting transmission housing is more suitable for vehicle and car structure.

Engine Covers

These covers benefits due to zinc’s resistance to corrosion and its ability to withstand high temperatures. We choose ZA-8, which contain higher aluminum element,ensure the engine covers high corrosion resistance,lightweight and tight tolerance dimensions. Also zinc die casting covers can protect the core part of the car and vehicle well and prevent the engine crashing from dropping weight and impact.

Brackets and Supports

Zinc alloy is so easier to shape intricative zinc die casting parts. As low melt point metal material, which can be molten at lower temperature than aluminum one. It can be shaped into intentional shaped precision zinc die casting automotive component, fast cooling , something like this. It also save more labor cost. Selecting Zamak 3 as the best material, and casting intended shaped brackets and supports, which is durable and maintain integrated structure and high mechanical properties. Sometimes, as count weight that maintaining the balance of the fuel car and EV.

Electrical Connectors and Terminals

Depending on Zinc’s electrical conductivity, along with its corrosion resistance, miniature zinc die casting electrical connectors and terminals are made of Zamak 2, bring more benefits and lower cost. That is ideal for sensor housing and connector,and brings overall vehicle performance and longevity.

Door Handles and Lock Mechanisms

Automotive door handles and lock mechanisms are often made from zinc alloy due to zinc alloy specific properties. These components that experience frequent used and exposure to the air, and uneasy to discolor and nodize. Because zinc alloy is easy to cast and strong corrosion resistance. Additionally, zinc casting parts can be finished in various ways to enhance aesthetics, as a popular choice for visible parts like door handles.

Heat Shields

Zinc die casting heat shield may protect sensitive components in automotive sector. They are common for the follow applications.

- Heat Shield Panels: These flat or contoured panels protect sensitive components from engine heat. and ensures the sensitive module running normally.

- Insulation heat Plates: These parts may back to the some heat components togehter to further enhance thermal protection.

- Heat Dissipation Headlight Housings : Zinc die casting headlight housings, which has reasonable heat dissipation, remain the headlight works better.

Fuel System Components

Corrosion resistance is crucial here. Zinc die casting is a suitable choice for fuel injectors and fuel line fittings and is favor of automotive fuel system components include the follow components.

- Fuel Injectors: Zinc die castings provide high strength and precision metal components for fuel delivery, ensuring efficient engine performance.

- Fuel Line Fittings: These components require corrosion resistance and reliable sealing, This request high precision design and strict structure. Zinc die casting is ideal option, and provide high performance and durable hardware line fittings.

- Automotive Fuel Pump Housings: Zinc die casting is ideal for durable and lightweight housings that protect internal mechanisms. ZA-8 is the best option for castable material,which remain weightlight and high strength and corrosion resistance.

- Fuel Filter Housings: Zinc’s corrosion resistance ensures longevity and reliability in filtering contaminant vessel.We choose Zamak 3 to produce high quality fuel filter housing in large volume at high effective.

- Fuel Tank Components: Parts like brackets and connectors have a good corrosion resistance of zinc’s properties for structural integrity and resistance to fuel exposure.

Require automotive components to enhance overall vehicle performance, reliability and reduction of the car and EV price. Zinc die casting just meets the demand of automotive components market development. These applications highlight zinc die casting’s versatility and effectiveness in meeting the demands of the automotive industry.

Top Zinc Die Casting Manufacturer Provides High Quality Automotive Components

Top zinc casting manufacturers, TangSheng Hardware Technology will provide complete engineering and design service and high quality automotive components. Although it is one private company only, it has its ability to meet some unique demands, and provides high-quality automotive components. The below advantages as show.

- Advanced Casting Technologies: Renowned for precision die casting and high-performance parts for the automotive sector. Offers advanced die casting solutions with a focus on lightweight components and complex geometries.

- Well-experienced Engineering Team: Specializes in custom zinc die casting design and manufacturing, Accept various OEM and ODM projects.

- Automation streamline production: Advanced die casting machines equipped with smart robitic hands and surface finish post-process precision equiment.

- Strict Quality Control System: ISO 9001 and IATF 16949 , these certificates is based of producing high quality automotive components, so its quality is guaranteed.

- Advanced Die Casting Machines: 8 sets of different tonage hot chamber die casting machines, and suitable for various appearance and functionalites design metal die casting processes.

The manufacturers focus on precision, durability, and adherence to industry standards, meet optimal performance of automotive components. Our zinc die casting components is to meet automakers requirement, Also we will produce high quality and precision casting parts.

Conclusion

Predicting automotive zinc die casting market is to grow significantly, driven by the demand for lightweight materials and the rise of electric vehicles (EVs). Zinc die casting offers advantages such as excellent mechanical properties, corrosion resistance, and cost-effectiveness. This makes it suitable for critical components like transmission housings, engine covers, and electrical connectors. The market will also benefit from advancements in automation and sustainable manufacturing practices, as companies seek to reduce environmental impact. Overall, zinc die casting is positioned to play a vital role in meeting the evolving needs of the automotive industry during this period.