Metal Die casting have common two types of die casting processes, which are cold chamber and hot chamber die casting processes. In modern industrial Manufacuring, These two types of main die casting is account for 80% overall die casting manufacturing industry. Hot chamber die casting is suitable for lower melting point metal alloys, such as zinc, magnesium, lead and tin alloys. However Cold chamber die casting is for higher melting metal, such aluminum, copper, iron and stainless steel. As hot chamber die casting technoloy expert, I will have an overview of hot chamber die casting: material, process and cost.

What Is Hot Chamber Die Casting?

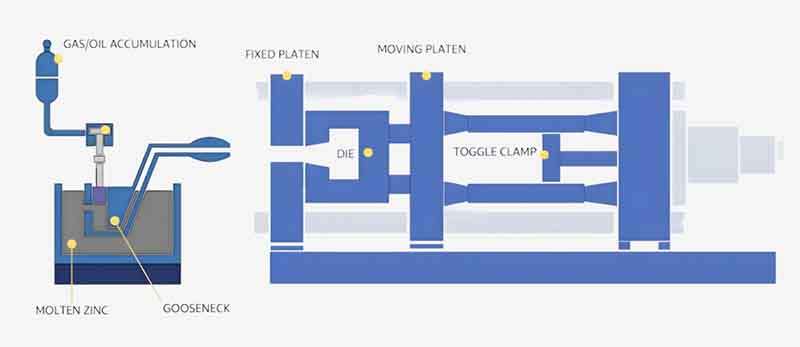

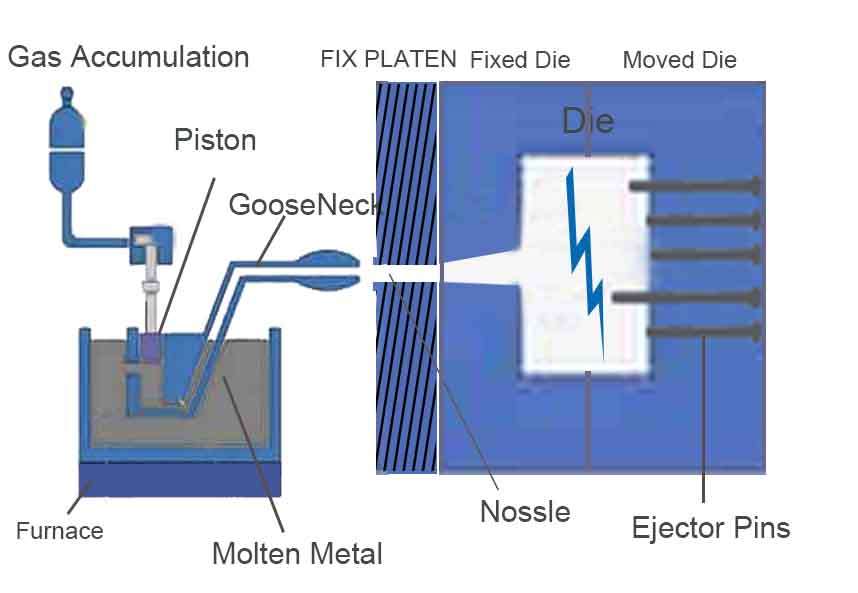

In the die casting, molten furnace is integrated with the machine. Feeding the metal material into pow, and melting metal material and overflow impurities and keep purified and steady temperature molten matail for injection. Though gooseneck mechanism, The hydraulic piston pushes the molten metal into the preheated die. Then under high pressure the molten metal flow fills into the die fully, cooled and solidified, the die is opened, the desired cast part is ejected out of the die. So hot chamber die casting is ideal for low melting point metal, such as zinc, lead and tin alloys.

The hot chamber die casting has a gooseneck injection mechanism, and enables injecting the molten metal into the cating die directly and form quickly. It has the below injection components for process.

- Furnace

- Gas Accumulation

- Gooseneck

- Piston

- Nossle

- Dies

- Ejector Pins

The process needs filling the metal into the pot pool only, the furnace melt the metal and filter impurities within molten metal. Through the gooseneck mechanism, die casting machine add pressure with gas accumulation and push the piston and the melton metal into the pre-heated die, inside vaccum die, the molten metal fill the core and cavity of the die fully. And Cools the die and solidifies metal die casting part. The die opens, and eject the cast part with ejecotr pins.

The hot chamber die casting are ideal for lower melt point metal, and have a fast injection, shorter cooling time and excellent surface finishing.

Material Is For Hot Chamber Die Casting

These materials all blong to lower melting points metal, below 430 degrees, they can become the molten metal, have a lower energy consumption. Each metal has also their own metal unique properties for specific functional requirements and environment applications.

| Metal Alloy Items | Material Examples | Characters | Applications |

|---|---|---|---|

| Zinc Alloys | Zamak 3, Zamak 5 ZA-8 | Excellent dimensional stability, High ductility & impact resistance and easy to cast | Automotive parts, hardware, electronics |

| Magnesium Alloys | AZ91D, AM60B, AE44 | Extremely lightweight (~35% lighter than aluminum), Good stiffness & damping properties and excellent machinability | Aerospace, electronics, automotive |

| Lead Alloys | Lead | Very low melting point, high density, and soft, easy to cast | Battery terminals, radiation shielding |

| Tin Alloys | Tin | Very lowe melting point, under 200 degree, | Battery terminals, radiation shielding |

Hot Chambe Die Casting Process Guide

Hot Chamber Die Casting is Cost-Efficiency

In industrial manufacturing, high volume cast parts are produced with hot chamber die casting manchines by die casting manufacturers. With The Technique Of Supporting Casting Lower Melting Metal With Hot chamber Die Casting Machines consistent optimization, manufacturers can produce more preminiumer metal die casting components under its unique technique. Because hot chamber die casting is cost-efficiency, which is reflected from the below key points.

1. Lower Operational Costs

Fast cycle times: The low melting points metal can cool quickly and solidify and ejected out from the mold, reduce cast cycle times.

Lower Energy Consumption: The low melting points metal saves energy consumption, under lower temperature, these metal are molten completely and maintain consistent temperature.

Automatic Production Lines: Easier automatic production lines saving more labor cost, and keep high efficiency mass production.

2. Less Waste Material

High Precision Casting Die : The die is made of high speed tooling steel, which is processed by cnc machining, milling, turning, grinding and EMD. So the casting die is high precision.

Excellent Metal fluidity And Mechanical Properties: These lower melting points metal have excellent fluidity when they are molten, and create a fine surface finishing. Also these metal have a good mechanical properties and create an integrated structure. This will reduce defective rates, and less waste material during injection.

100% Recycled Material : Such zinc, magnesium, lead and tin are all 100% recycled when they become useless application, and remolten and recast.

3. Lower Tooling Wear Vs Cold Chamber Die Casting

The toolings always achieve lower temperature when mass production is conducted with hot chamber die casting machines. The toolings wear is more less than one of cold chamber die casting, and makes the tooling life time too longer, and save more tooling costs.