IATF 16949, is on base of ISO9001 International Quality Management System, Focus on automotive industrial product design, process, installment testing and quality control, strict follows their execution standard. Which encompasses ISO 9001 certificated management regulation, with additional automotive-specific requirements. So IATF 16949 normalizes product’s design & process in enterprise. As one of die casting manufacturers, we want to produce some interior and extorior components in automotive industry, the IATF 16949 management system should be certified. Take a closer look at our product quality standards.

IATF 16949 Standards Implemented In TangSheng Hardware Technology

TangSheng Hardware Technology is one of comprehensive industrial factory, which encompasses die casting process, plastic injection molding and product assembly, In order to avoid body hurt and accidents happening in steamline production, we allow our employees to do only white shift and additional overwork method. Our factory had passed IATF 16949 Quality Management System Certification In December 2024, IATF 16949 normalizes product’s design & process in enterprise. It allows our factory to produce some components in automotive industry exception of general hardware and plastic parts. IATF 16949 will carry through all process steps, from raw material source to finished product inspect and testing standard, each employee in factory should follow the industrial quality management system strictly, and ensure each step implement professional operation guide.

- Outsourced Raw Material Inspection and testing, follow the client requirement,

- Product process & design must follow APQP(Advanced Product Quality Planning), FMEA, Control Plans, PPAP (Production Part Approval Process), and customer-specific requirements. Design review, process validations and audits.

- Various molds and dies manufacturing depends on the engineering drawing and operator operating instructions. Combine with client verify and design adjustment, Makes high quality precision molds and dies.

- To achieve highly effective mass production under IATF 16949, we implement process controls, continuous improvement, and strict adherence to automotive quality standards. With some advanced inspection instruments, ensure the processed components high quality.

- In finished product assembly aspect, we carry out assembly qulity contol, and inspection and documentions. Implement PPAP (Production Part Approval Process) for assemblies.

Aluminum Casting Impregnation Reduce Shrink Porosity And Gas Porosity

Aluminum casting impregnation In IATF 16949 improve some large size aluminum casting parts suface finish, maybe with resin, vacuum and pressure technology, avoid shrink and gas porosity on the surface of aluminum casting parts. Especially these components are used for oil path and air pressure. To prevent oil and air leakage from porosity voids, the aluminum casting impregnation should be done after as-cast parts, includes cleaning, sealing and curing. Also fits the quality audit standard of automotive components.

Meanwhile leak testing is indispensable in aluminum casting impregnation. Our facility offers complete leak testing capabilities for customer who want to added value service. we have experience perform leak testing after aluminum casting impregnation for different aluminum alloys and complete many successful turnkey projects.

- Air Pressure Decay Test

- Helium Mass Spectrometry

- Dye Penetrant

- Water Submersion

- Vacuum Decay Test

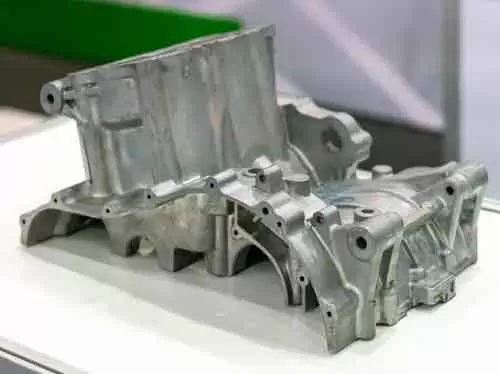

Precision Zinc And Aluminum Die Castings CNC Machining

Close tolerance CNC machining makes as cast zinc and aluminum die castings more accurate dimensions and fine surface finish. In automotive components applications, these as-cast zinc and aluminum die castings should be machined precisely, and and inspected by projector and 3 coordinate measuring machines, and handle in-process checks, first piece layouts. We equip with 4 sets of two heads of precision engraving machine to finish our car key case cover dimension position and surface finish treatment. Whenever zinc or aluminum die casting, we will comply with industrial process standard in IATF 16949, and handle strictly quality of products, provide high quality automotive applicational parts.

Die Castings Surface Finish Compliance in IATF 16949

These die casting parts in automotive applications should comply with IATF 16949 standard, so the surface finish options for these die castings follows some strict process control and quality standard. And meet the requirement of functionality, durability and customer satisfication. Complying with industrial standard and customer specific requirements, we require our supplier to offer high standard die castings outsourced by surface finish treatment. Common surface finish compliance for automotive application should be implemented in house testing lab.

- Pitting/Blowholes

- Scratches

- Orange Peel Texture

- Gloss Variation

- Bond testing