All-Around Services For Business Partners and Clients

.

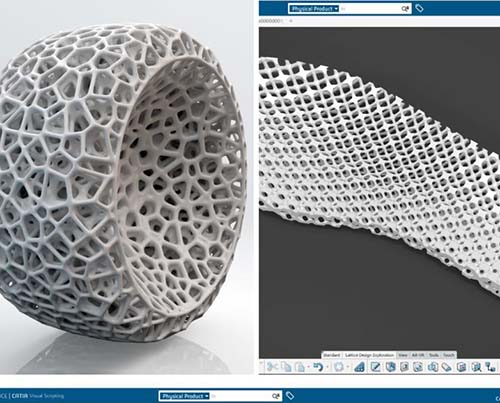

Product Design

—— our services

This is a brainstorm action, it need designer and engineer have a full collaboration on their work. With his moment spirit, Designer should have a creative idea and his visual model, then add various patterns and text, gain an attractive points. But also its functions conform to client’s requirements, too. This kind designed visual 3d Model is confirmed and decide to sign the contract and begin to a new sample trial order. Product design is commonly done by well-experienced senior engineer in our company.

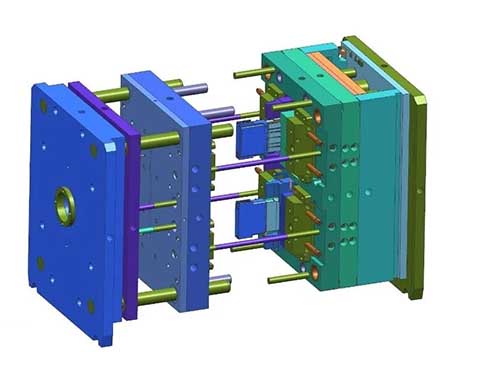

Mold Design

——— OUR SERVICES

In accordance with the product’s 3d visual model ,Engineer begin to design the mold for visual product. With the material that product is made of, our engineer will design different mold. If the product is in need of hardware and metal material. They will consider of zinc alloy cast die. If client require a plastic product, engineer may be design a set of plastic injection mold.Mold design is either needed of exquisite technique or troubleshooting some debates with mold manufacturing worker in molding room.

Mold Manufacturing

——- OUR SERVICES

Want to make the mold for product manufacture, need change visual 3d designed mold into real mold. It will pass the following procedures. Include of Cutting, Grinding, EDM, CNC Machining, Tapping and Milling ect. Then a rough mold is make out, but it also need to be repaired and modified, at last using the precision mold to have a trial, and inject first sample. Whenever metal cast die or plastic injection molding, it should pass a serial comprehensive procedures. So the mold room has our sophisticated technicians and well-experienced operators.

Zinc Alloy Casting Parts

——– OUR SERVICES

Zinc alloy casting parts are used for small and medium size of gifts, electric components, furniture’s parts and decoration accessories. As a kind of special metal material, Zinc alloy material is more easier to be processed at lower temperature. Also its metal properties and glossiness makes its surface can be treated well. TangSheng Hardware Technology have been engaging into zinc alloy casting prcoess for 10 years or so. Being equipped with 8 sets of zinc alloy casting machines, can meet different demands from clients and business parnters. Such as Electronic components and automobile parts, even gain a good reputation in the market at home and abroad.

Plastic Injection Parts

——– OUR SERVICES

In order to meet the parts’ requirements of car key cover or case from our regular customers, We introduced 8 sets of full automatic plastic injection machines. Equipped with robot hands so that can do picking and taking action, largely reducing the risk of scratching and fingerprints. Meanwhile, we have these machine, not only meet the supply of our car key case’ parts, but also we can produce another plastic parts for other usage. At all, most of plastic injection parts are used for automobile and electronic communication fields.

Casting part Post Process

——- OUR SERVICES

Zinc alloy casting parts are very rough when they are made out from die. Firstly, these parts should be deburred, this is a simple treatment, separating the water gap from the part. They are needed to deliver to post process dept to process. the sharp and burr on some parts should be removed, worker use scissor and knife to get rid of them, but some casting parts is not easy to be treated by this simple process. They may be processed with precision machines. CNC machining process is selected as common process for treating of zinc alloy casting parts. For as a small and medium size of metal part, it need a small tolerance, especially, electronic communication parts.

Assembly Testing and Package

——– OUR SERVICES

Zinc alloy casting part and plastic part are installed together at this place, All outsourcing parts are back to our assembly workshop. Zinc alloy casting cover and inner plastic mat, composed into a perfect finished product. Or zinc alloy casting enclose and plastic USB flash drive disk lock, and insert disk memory chip and electric circuit, we will test a flash drive disk features. At last step, that is finished product’s package. In accordance with customer’s requirements, choose respective package methods and package material, With the consideration of security, we often adopt plastic absorption box or hardness box with inner soft sponge

What’s Your good idea?

Do you really want to find one of professional metal casting factory to finish your project? If you want, please contact us by Email , We also hope to have a chance to work with you