What is Rapid Prototyping Service ?

Rapid prototyping service means quickly design a physical model or prototype with using 3D computer-aided design (CAD) software. Then engineers and designer follow the designing drawing to process first samples before mass production,and test their design and identify their concept into actual object. The prototyping service must be faster, cost-effective and high quality turnkey project service. Through optimzing process and technique, deliver the custom process project to the client in hours or a few days.

Plastic 3D Printing And Metal Die Casting Prototyping Services

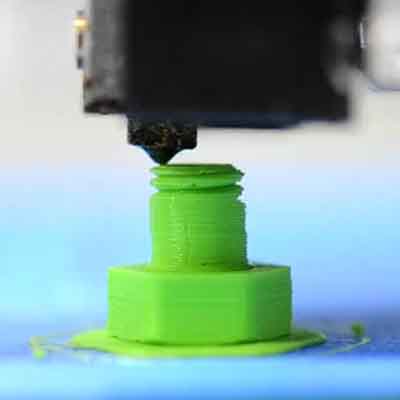

Plastic 3D Printing Prototyping Service

TangSheng engineers and designers design visual 3d product model with CAD software, and convert to STL/3MF files. Then import these files into 3D printing machine, genearate g-code to execute machine orders, and do a 3d prototype printing. At last, you will get a plastic sample with 3d printing machine. Below is clear steps.

1.Option For Plastic Material

We choose the best material among the below common plastic material(PLA, ABS, PETG, Nylon, TPU and Resin) depends on the application of the plastic part. Meanwhile we designate the right 3d printing machine to work.

2. 3D Printing Process

Import the according 3d printing file into the 3d printing program, and setting 3d pring machine and start 3d printing process.

3. Post-Processing (Finishing)

The printed plastic model maybe need minimized post-process and finish the smooth surface finish option and improve the appearance of the printed part.

4. Inspecting & Testing its application

The rapid prototyping part will be inspected and test its application and fast finish the turn-key project sample confirmation issue.

5. Deliver First Sample to The Client

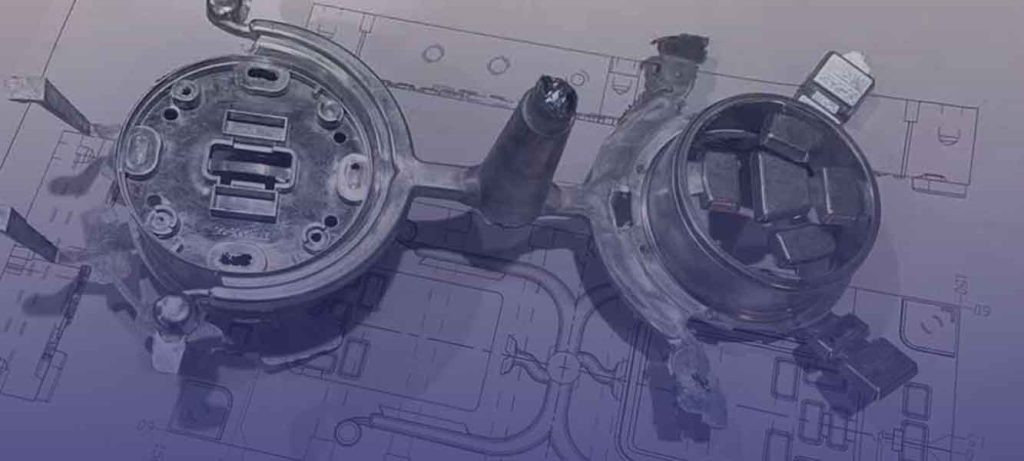

Metal Die Casting Prototyping Service

Metal die casting prototypes need be made by die casting process. We suggest that the precision casting die should be designed and manufactured. Depends on the material of custom die castings, select the proper die casting method to cast the prototype. Include two types of die casting processes, which are cold chamber die casting, and fits high melting point metal alloys material and hot chamber die casting,suitable for low melting metal process at high efficiency.

Design & Tooling Preparation

The precision metal die casting part should be cast by high precision high steel die, our engineers should design the technical drawing for the high precision die and have a visual simulation test and further improvements.

Mold Fabrication

Mold manufacturing involves of best choice of tooling steel material, the production of the core and cavities of the die and form complex geometries and smooth surface. in another one, the life of the die is very important and accept reaptive impact and frication at several times.

Casting Process

Depends on the different metal material , we select the right die casting method. Zin alloy is suitable for hot chamber die casting process, which being ready for molten zinc alloy, and by goosechannel system and cast the die casting part. However, aluminum alloy is molten in furnace pool, dlet the molten aluminum into hopper and inject the die and cast it.

Post-Processing (Optional)

The metal die casting prototype needs die casting process and further post process. these as-cast parts with excellent surface finish and dimensional accuracy need the further CNC machining.

Inspect And Test The Die Casting Part

Deliver Prototypes to The Client

Plastic 3D Printing VS. Metal Die Casting Prototyping Services

| Plastic 3D Printing | Metal Die Casting | |

|---|---|---|

| Material Differences | PLA, ABS, PETG, Nylon, Resin (SLA),Low to Moderate (up to ~120°C for some plastics),Layered texture, need further post-process | Aluminum, Zinc, Magnesium,High (200–400°C, depending on alloy),Heavier than plastic but stronger,Smooth |

| Production Speed & Lead Time | Hours to 2 days (no tooling needed),just upload a 3D file | 1–4 weeks (mold fabrication required),requires mold design & machining, |

| Cost Comparison | direct printing, no mold cost, suitable for low quanity and rapid prototypes, | Need the casting die to cast prototypes, need mold cost, but the low production cost. |

| Accuracy & Tolerances | ±0.1–0.5mm (varies by technology),Requires post-processing | ±0.1–0.3mm (better consistency), further post-processing |

| Strength & Durability | Tensile Strength, 30–100 MPa, can endure frequent impacts, poor faitigue resistance | Tensile strength, 200–400 MPa, withstand repeative impacts, excellent faitigue resistance |