Rapid Prototyping Services

Rapid prototyping services mean provide high quality prototype for client’s specific requirements in short time. Hereby there is two ways to realize. One method is designing die and molding tool, then produce a set of molding tool, and inject material into the mold and form ideal prototype. Another method is straightly printing prototype with 3d printing machine.

Step Content Table

What Are Rapid Prototyping Services ?

Rapid prototyping services are the processes that quickly design a physical model or prototype of a part or product using 3D computer-aided design (CAD) data. Then engineers follow the design drawing to process first samples by rapid process method before full-scale production,and test their design and identify their concept into actual object. Depends on demand of product specifications from the client, manufacturers can make rapid prototypes with rapid process methods, which involves using 3D printers to create physical models or using precision machine to process prototypes quickly and efficiently.

Key Features For Rapid Prototyping Services

| Features | Detail Description |

|---|---|

| Fast Speed | The first samples should be finished in a few hours and days, engineers and designers focus on the custom project, make the design drawing, select faster process method, and process the first samples in shorter time and deliver them to the client. |

| Best Cost-Effective | Depends on the functions and applications, our engineers and designers take some optimal design and process methods and reduce the cost of first prototypes, and reach win to win development model with the client. |

| Process Approches Adopted | 3D Printing – FDM, SLA, SLS, DMLS, etc.(making some intricate design plastic parts) Vacuum Casting – For small-batch silicone molds. Injection Molding – For functional prototypes, include of plastic injection parts and metal die casting parts. |

| Prototypes Inspection and Test | First samples should be inspected by some precision measure instruments, such 3d dimension tester, Ray measuring instrument and tape adhesive testing, and have an appriorate assembly testing. |

Provide Around Rapid Prototyping Services

TangSheng Hardware Technology provides rapid prototyping services include of plastic 3d prototype printing and Die Casting prototype services. Depends on sample application and specific functionalities, engineers select the best rapid prototyping method, make desired sample in short time at best cost- effective. deliver them to the client. The below has a description from two aspects.

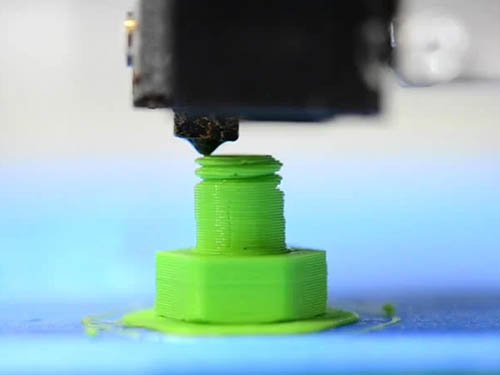

Plastic 3d Prototype Printing Service

Firstly,Our designer can design visual 3d product model for you according to your requirements. After you confirm that you want to have a first sample, our engineer arrange to do a 3d prototype printing with the designed visual 3d product model though 3d printing machine. At last, you will get a plastic sample with 3d printing machine. In detail we list key links to everyone.

- Plastic Material Options

- Choose 3D Printer

- Setting Up the Printer

- Finish Rapid Prototypes

- Inspect and Test Prototypes

1. Material Options Have A Wide Range

- PLA (Polylactic Acid): An affordable and commonly used bioplastic, don’t require high durability.

- ABS (Acrylonitrile Butadiene Styrene): Tougher and more durable, suitable for functional parts and daily produts.

- PETG (Polyethylene Terephthalate Glycol): A strong, food-safe standard plastic with strong impact resistance.

- Nylon: Highly flexible and durable, good for functional prototypes and end-use products. With solid and toughness, used in machenical components.

- TPU (Thermoplastic Polyurethane): Flexible,like rubber, seal and cover.

- Resin: making high-detail, smooth-surfaced prototypes, used in SLA/DLP printing.

2. 3D Printing Capability

SLA (Stereolithography): Offers high-detail, smooth-surfaced prototypes, suitable for resin.

KINGS 1700pro 3D Printer

| Items | Parameters |

|---|---|

| Max Printing Size | 1700*800*600mm |

| Rated Power | 2.2kw |

| Beam Size (diameter @1/e2) | 0.06-0.8mm (Variable Beam) |

| Max Scanning Speed | 15m/s |

| Layer Thickness | 0.05mm~0.20mm |

| Wave length | 355nm |

| Scanning System | Germany Scanlab |

| Machine Size | 247cm(W)*168cm(D)*230cm(H) |

| Machine Weight | 3600kg |

Die Casting Prototyping Service

Some metal prototypes need be made by cnc machining or die casting. The process involves creating parts by injecting molten metal into a mold (or die) under high pressure. Then these as-cast parts with excellent surface finish and dimensional accuracy need the further CNC machining. This kind of custom die casting project means that supplier ofter die casting and cnc machining protytyping services.

- Design the die

- Options of Die Material

- Die Casting Process

- Rapid Prototype Process

- Inspect and Test Prototype

1. Designing And Manufacturing the Die

The die consists of two parts: Cavity (female) that shapes the outer surface of the part. Core (male) that forms the internal features. We use software like SolidWorks, Fusion 360, or others to design the 3D CAD model for the part. Or according to the real sample client present, we design the mold that produce the part in high volume. Then our worker will manufacture the precise casting die according to the drawing of casting die designed by our engineers.

2. Selecting the Metal

Zinc is lower melting point metal, through die casting process, and make high precision die casting components with complex shape and tight tolerance dimensions and functionalities.

Aluminum is Lightweight, with good strength and corrosion resistance. It has High strength and ductility, suitable for complex parts.

Magnesium is Lightweight, with excellent strength-to-weight ratio, and has a strong strength and toughness.

Copper or Brass has high conductivity and corrosion resistance, and good hardness. They can be used for connector and electronic components for circuit connection.

To meet the specific requirements from client, we will use these common metals in die casting, and choose the best metal material to make first sample.

3. Die Casting Process

We have two types of the hot-chamber or cold-chamber die casting method for metal die castings.

Hot-Chamber Die Casting: For low-melting-point metals like zinc, magnesium, or lead. Integrated melton metal pool with the machine, the metal is melted in a chamber connected to the die casting machine, and the molten metal is injected directly into the mold.

Cold-Chamber Die Casting: This is used for high-melting-point metals like aluminum or brass. The molten metal is melted in a separate furnace. Transferring the melton metal to the casting machine using a ladle when die casting process is proceed.

4. Rapid Prototype Making

Employing skilled-well technician in metal die casting process, to handle various die casting operation skills, and troubleshoot the defects of die casting part in short time, and improve die casting process and ensure the best quality of part and accurate tolorance of the part, if neccessary die casting parts cnc machining process is available. We can deliver high quality rapid protoype to our client.

5. Inspecting and Testing

Check that the dimensions match the specifications of client requirements. According to the sample’s intended use, to undergo stress, wear, or fatigue testing to verify its performance. If neccessary, assemble them with other revelant component, testing their practical usage.

6. Advanced Die Casting Machines

Cold Chamber Die Casting Machines

| Machine Name | Brand | Equipped with Robot hand | Machine Type (Tons) | Quantity (set) |

| Cold chamber die casting machine | LiJin Brand | Yes | 200 tons | 2 |

| Cold chamber die casting machine | LiJin Brand | Yes | 320 tons | 2 |

| Cold chamber die casting machine | LiJin Brand | Yes | 400 tons | 1 |

| Cold chamber die casting machine | LiJin Brand | Yes | 500 tons | 1 |

Hot Chamber Die Casting Machines

| Machine Name | Brand | Equipped with Robot hand | Machine Type (Tons) | Quantity(set) |

| Hot chamber die casting machine | LiJin Brand | Yes | 50 tons | 2 |

| Hot chamber die casting machine | LiJin Brand | Yes | 80 tons | 2 |

| Hot chamber die casting machine | LiJin Brand | Yes | 88 tons | 1 |

| Hot chamber die casting machine | LiJin Brand | Yes | 160 tons | 1 |

Conclusion

In summary , rapid prototype services include plastic 3d printing prototype and die casting prototype. Cetrtainly 3d printing can create good appearance of a product only, regardless of its structure and durability. However as Metal die casting prototype, engineers can consider of many parameters and durability when the product is produced, also its structure is very solid and practical usage. So we should depend on application and functionality of the kind of product to decide the cost-effective process method.