Society is progressing, Technology Creation is developping, Technology is changing our life and work, computer have been popularized, so information transmission have just swaft into digitization. Application of USB flash drive disk have been used widely. This small size thing, can bring more convenience and portable to you, but the core of it is electric circuit and chips, which need a durable and strong cover to protect the core, So I think USB flash drive disk should come with a good protector. That is zinc alloy USB flash drive disk housings, which can either playing a electrical connector or protecting the electric circuit and chips well.

Zinc Die Casting USB Flash Drive Disk Housings Manufacturing Process

Preparation For Die Casting Process

Firstly, We have a good preparation for high effective mass production. It is need of melting Zamak 2 in the integrated furnace, filtering impurites within the molten metal by overflow method. And maintaining steady temperature molten metal in the reservior. The low melting metal require 380-420 degrees to become liquid metal, exhaust less heat energy.

Metal Part Cast Cycle

Secondly, We adopt hot chamber die casting machine to produce mass products at high efficiency. By gooseneck mechanism, the machine’s hydraulic piston push the molten metal into the pre-heated casting die under high pressure. Rely on high fluidity of molten metal, the metal flow fill the cavity of the die fully in a few seconds. The casting die accepts water cooling, and makes the molten metal solidified quickly, then ejected from the die.

As Cast Part Post Process

When Our usb flash drive housing is casted into the rough part by our advanced casting machines. As as-cast part, which may be deburred for removing excess gate gaps and hidden burrs. Worker use mechanical and munual options for high effective post-process. include of viberation for removing gate gap, manual filing, abrasive wheel for grinding the burrs, sand belt for grinding the burrs and cnc machining for high precision process.

The Cast Part Surface Finishes

The usb flash drive housings deburred may need more appeal and aethetic appearance for longnity and promotion purposes. Die casting manufacturer should deliver them to outsourcing factory for excellent surface finishing. It involves of electroplating, powder coating, printing, etching,laser engraving and anodization.

Testing And Assembly

Inspecting the outsourcing processed parts, and conduct bond power and corrosion resistance testing. Sometimes some parts require having a fit assembly for finished products and functional parts. Undoubtedly we have design and manufacture more shaped casting usb flash drive disk cover due to different demands from business partners and clients, For us, we produce zinc alloy hard disk cover, meanwhile we also inject plastic parts for hard disk.

Die Casting USB Flash Drive Housings Are Various

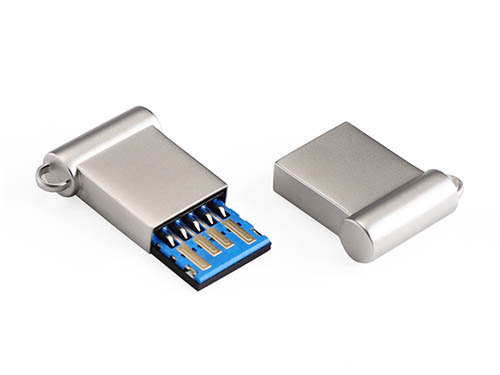

Casting USB flash drive housings include of three kinds due to its functions and applications, these casting covers are all made from zinc alloy material

Long Tail Cover

This kind of hard disk cover is only decided by the flash drive disk’s appearance and designing style. some consumers like long tail flash drive disk due to his hobby and habit.

Short Tail Cover

Compare to long tail cover , there is a short tail cover, its design is depended by usage scenario and work environment, in fact , both items have a same function of storing data and transmitting data.

Turned Cover

Another kind of cover is turned cover, in general condition, it is designed to have double ports, include of USB 2.0/3.0 port and mobile smart port. So the turned flash drive disk can meet the special function of transmitting data from fixed device to mobile device.

Turned Disk Housings

Long Tail Disk Housings

Short tail Disk Housings

Indispensable Post Processes For Zinc Die Castings

Metal casting part is rough when it is just casted, in common condition, the surface of it is very rough, with a thin sharp and burr. So it should be deburred firstly, sometimes, common worker can remove the burr with scissor and pliers, if some sharp and burr is not easily removed or repaired, so cnc machining process should be used. but also the surface of the casting part is still rough, So polishing process is necessary. I will have a conclusion, the metal casting part should be processed in the follow procedures

- Metal Die Casting Parts Polishing

- Die Casting Parts CNC Machining

- Metal Die Casting Parts Coating

- Die Casting Parts Electroplating

- Metal Die Casting Parts Deburring

- Laser Marking On Die Castings

If you want to know more about us , you can contact with us or take a message to us on line, we welcome to visit us ,

What’s Your good idea?

Do you really want to find one of professional metal casting factory to finish your project? If you want, please contact us by Email , We also hope to have a chance to work with you