Zinc alloy die casting switch box, which has steady integrated structure,tight tolerance dimension and personalized design appearance. Because the metal switch box is portable and durable, so it is always used for light controlling switch in hotels and some noble places. The follow let everyone know it more about zinc alloy die casting Switch box project.

Advantages Of The Zinc Casting Switch Box

For a high-end switch box in a hotel setting, zinc alloy die castings are durabe, aesthetic appeal, and reliable. Especially the zinc die casting switch boxes can be used in luxury hotels and high grade sites. These parts are made in accordance with client unique requirements and decoration purposes. Rely on the below advantages:

Precision and Aesthetic Design

Zinc alloy’s excellent castability creates high-end switch boxes with intricate and refined designs, especially hotels often want sleek, modern designs for decorating luxury interiors. Its precision dies and good fluidity of melton zinc alloy ensures the dimensional tight tolerance and aesthetic design gemotries. .

Durability and Resistance to Wear

Hotel switch boxes are frequent use, so durability. Zinc alloy is highly resistant to wear and impact, so zinc casting switch box affords high frequency usage and fine wear resistance over time.

Corrosion Resistance

In humid environments like bathrooms or coastal hotels, More corrosion resistance parts are required. Zinc’s natural resistance to corrosion ensure zinc die casting switch box can be used in these places for longer time and maintain its high quality and functionalities.

Customizable Surface Finishes

Zinc die castings can be easily plated, painted, or finished with various coatings, especially customize zinc casting switch boxes, which are treated to match their interior design. From polished chrome to matte finishes, depends on luxurious feel of the room in hotel and high grade sites.

Cost-Effective for Large-Scale Production

For hotels, where each room requires several switch boxes. Zinc alloy die casting is cost efficiency for large-scale production with high quality. Its lower energy consumption, recyclability, each fast cycle in mass production reducing the average cost of production in high volume quantity.

Fire Safety

Zinc alloy has favorable properties when it comes to fire resistance. High-grade switch boxes in hotels must adhere to strict fire safety standards, and zinc can help in meeting these standards while still offering a high-end appearance.

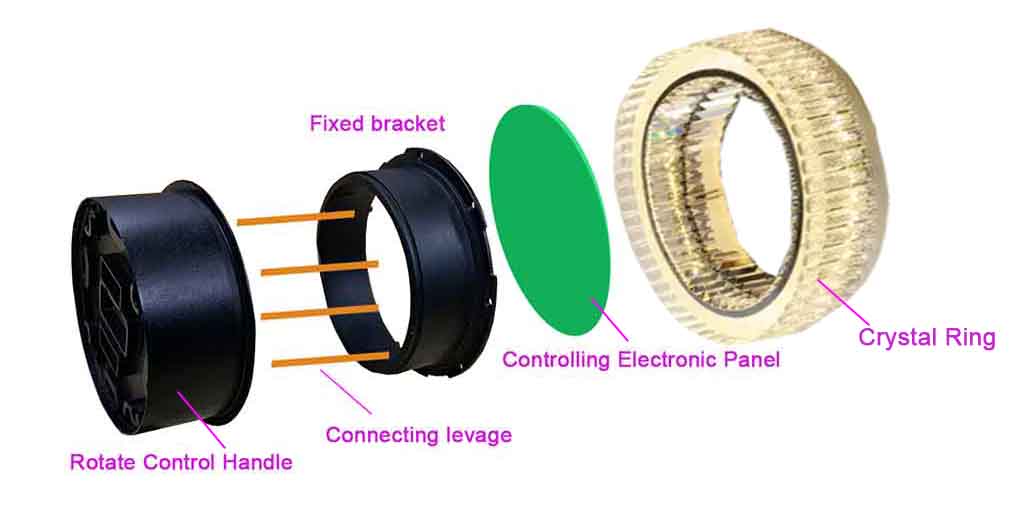

Zinc Alloy Die Casting Switch Box Has Unique Structure

This unique design ensure that more match client’s control switch, also have a good appearance. It is portable and durable. Either protecting electronic circuit and components well, or install and fix electronic circuit control reasonable. This is a item of high grade switch structure design component, at this time, also reflect that our engineering design and technique is excellent.

GET IN TOUCH