As one of professional manufacturer, we not only produce zinc alloy, but also process plastic injection parts. Sometimes, We should have some adjustment for parts production, so it can involve of mold manufacturing. However this needs more technology to support our business. The follow material is often used , We hope more intentional client and business partner to learn more about them.

Zinc Alloy Material

Zinc alloy is a material made by combining zinc with other metals to improve its properties, such as strength, durability, and resistance to corrosion. Common metals mixed with zinc in zinc alloys include aluminum, copper, magnesium, and sometimes lead or tin.

Zamak (Zinc, Aluminum, Magnesium, and Copper): Used in die-casting due to its excellent fluidity and precision in molding. Common in automotive parts, household items, and electrical fittings.

Brass (Zinc and Copper): Known for its aesthetic appeal and used in decorative items, plumbing fittings, and musical instruments.

Zinc-Aluminum Alloys: Often used in applications requiring high strength and corrosion resistance, such as in the aerospace and automotive industries.

Zinc alloy material have been applied for many fields in our living and working, We are producing more zinc alloy products to meet many requirements in the market home and aboard. Because we focus on eco friendly of each product. So the following material should be all green and eco friendly.

UE Rohs Standard Test Report SGS certified

| Test Item(s) | Limit | Unit(s) | MDL | 001 |

| Lead(Pb) | 1000 | mg/kg | 2 | 19 |

| Mercury(Hg) | 1000 | mg/kg | 2 | ND |

| Cadmium(Ca) | 100 | mg/kg | 2 | ND |

| Hex Chromium(Ch) | – | ug/kg | 0.10 | ND |

| Polybromobiphenyl(PBB) | 1000 | mg/kg | – | ND |

| Monobrominated biphenyl(MonoBB) | – | mg/kg | 5 | ND |

| Dibrominated biphenyl(DiBB) | – | mg/kg | 5 | ND |

| Tribrominated biphenyl(TriBB) | – | mg/kg | 5 | ND |

| Tetrobrominated biphenyl(TetrBB) | – | mg/kg | 5 | ND |

| Hexabrominated biphenyl(HexBB) | – | mg/kg | 5 | ND |

| Pentabrominated biphenyl(PentaBB) | – | mg/kg | 5 | ND |

| Heptabrominated biphenyl(HeptaBB) | – | mg/kg | 5 | ND |

| Octabrominated biphenyl(OctaBB) | – | mg/kg | 5 | ND |

| Nonabrominated biphenyl(NonaBB) | – | mg/kg | 5 | ND |

| Decabrominated biphenyl(DecaBB) | – | mg/kg | 5 | ND |

| Polybrominated biphenyl ether (PBDE) | 1000 | mg/kg | – | ND |

| Monobrominated diphenyl ether(MonoBDE) | – | mg/kg | 5 | ND |

| Dibrominated diphenyl ether(DiBDE) | – | mg/kg | 5 | ND |

| Tribrominated diphenyl ether(TriBDE) | – | mg/kg | 5 | ND |

Reach Standard Test Report SGS Certified

Learn more about it , please download the file.

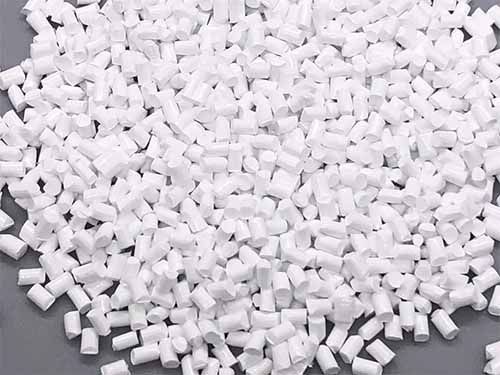

ABS Material

Acrylonitrile butadiene styrene (ABS) (chemical formula (C8H8)x·(C4H6)y·(C3H3N)z ) is a common thermoplastic polymer. Its glass transition temperature is approximately 105 °C (221 °F). ABS is amorphous and therefore has no true melting point.

ABS is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15% to 35% acrylonitrile, 5% to 30% butadiene and 40% to 60% styrene. The result is a long chain of polybutadiene crisscrossed with shorter chains of poly(styrene-co-acrylonitrile).

This is plastic resin raw material is largely used in many fields. Due to it is eco friendly and safety for people and animal, especially some precision parts for car and automobile, even though some electronic components, which is conformed with higher requirements.

Rohs standard Test Report SGS certified

- 1 mg/kg = 1 ppm = 0.0001%

- MDL = Method Detection Limit

- ND = No Detect

- “-” = Not Regulated

| Test Items | limit | Unit | MDL | 001 |

| Cadmium | 100 | mg/kg | 2 | ND |

| Lead(Pb) | 1000 | mg/kg | 2 | ND |

| Mercury(Hg) | 1000 | mg/kg | 2 | ND |

| Hexavalent Chromium | 1000 | mg/kg | 8 | ND |

| Sum of PBBs | 1000 | mg/kg | – | ND |

| Monobromobiphenyl | – | mg/kg | 5 | ND |

| Tribromobiphenyl | – | mg/kg | 5 | ND |

| Tetrabromobiphenyl | – | mg/kg | 5 | ND |

| Dibromobiphenyl | – | mg/lg | 5 | ND |

| Pentabromobiphenyl | – | mg/kg | 5 | ND |

| Hexabromobiphenyl | – | mg/kg | 5 | ND |

| Heptabromobiphenyl | – | mg/kg | 5 | ND |

| Octabromobiphenyl | – | mg/kg | 5 | ND |

| Nonabromobiphenyl | – | mg/kg | 5 | ND |

| Decabromobiphenyl | – | mg/kg | 5 | ND |

| Sum of DBDEs | 1000 | mg/kg | ND | |

| Monobromobiphenyl ether | – | mg/kg | 5 | ND |

| Dibromobiphenyl ether | – | mg/kg | 5 | ND |

| Tribromobiphenyl ether | – | mg/kg | 5 | ND |

| Tetrabrombiphenyl ether | – | mg/kg | 5 | ND |

| Pentabromobiphenyl ether | – | mg/kg | 5 | ND |

TPU Material

Thermoplastic polyurethane (TPU) is any of a class of polyurethane plastics with many properties, including elasticity, transparency, and resistance to oil, grease, and abrasion. Technically, they are thermoplastic elastomers consisting of linear segmented block copolymers composed of hard and soft segments.

This is a kind of special material , which is soft, and transparent, can be selected as water proof and dust proof map, As one of IATF 16949 certified enterprise, we produce car smart key cover, which is zin alloy die casting case and TPU water proof map are installed together, combined into a protector case for car smart key. So TPU Material is very important. We should choose best quality TPU for our metal case.

Mold Steel Material(Special Steel: 8418,718 and NAK80 )

Zinc Alloy Die Casting Mold

Zinc alloy die casting mold, we often choose 8418 steel , which is more advantageous, than H3 steel. it has a perfect strength and hardness , also wear-resistant. meanwhile we are often taking consideration of best zinc alloy raw material so that lengthen this mold life.

Plastic Injection Molding

When we have manufactured metal casting die, sometimes client require some plastic components to come with these zinc alloy metal parts. Then we should make some plastic injection molding to inject specific plastic parts to perfect these metal casting parts. In general, we choose such special steels to make plastic injection molding, which is made from 718 and NAK80.