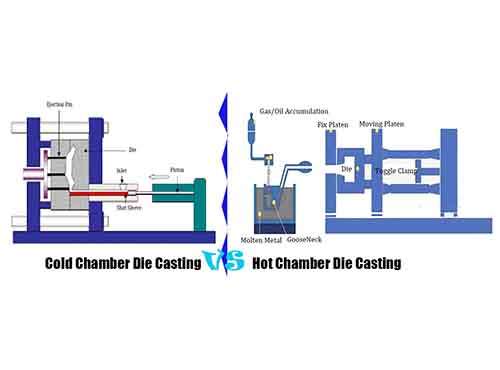

In metal die casting process world, Zinc alloy die casting has become popular in industries demanding high-quality, high tolerance dimensions complex shapes parts . Among these processes, the hot chamber die casting method stands out, speed, and cost-effectiveness. Producing high-quality zinc alloy die casting parts requires a handle of specialized techniques, machine operations. Today have a detail description for The Technique Of Supporting Casting Zinc Alloy With Hot chamber Die Casting Machines.

What is Hot Chamber Die Casting Process ?

Hot chamber die casting process is a meal manufacturing method, which producing precision metal parts, particularly with alloys that have low melting points. Such as zinc, magnesium, and certain lead-based alloys. This process is injecting molten metal into a steel mold (die) under high pressure to form intricate, high-quality parts. As a special manufacturing process, requires a handle of specialized techniques, machine operations. Here’s a detailed breakdown of hot chamber die casting process.

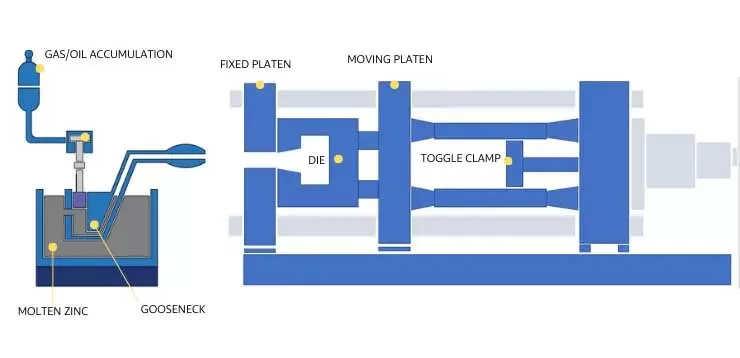

Key Components of the Hot Chamber Machine

The main components of a hot chamber die casting machine include:

- Furnace: It is integrated with the machine, it keeps the alloy in its molten state.

- Gooseneck Assembly: A tube-like structure immersed, which delivers the molten alloy to the mold cavity.

- Plunger: This is a hydraulic or pneumatic system that drives molten metal into the mold under high pressure.

- Die (Mold): It is made of hardened steel, it shapes the molten metal and consists of two halves—the fixed (stationary) die and the movable die. It decides How are Zinc Alloy Die Casting Parts Shaped.

Step-by-Step Process Guideline

Advantges Of Casting Zinc Alloy With Hot chamber Die Casting Machines

In industrial manufacturing, most zinc die casting parts are produced with hot chamber die casting manchines. With The Technique Of Supporting Casting Zinc Alloy With Hot chamber Die Casting Machines consistent optimization, manufacturers can produce high quality zinc die casting components under its unique technique. In another one, zinc good fluidity in molten status makes it forming smoother surface finish. Rely on designed precise high speed steel casting die, conduct smooth mass production in high volume within compared shorter time. But also create a smooth suface finish and reduce the work volume of post-process. It advantages reflects the below detailed descriptions.

1.High Efficiency Production Speed

The low melting points metal can cool quickly and solidify and ejected out from the mold, saving cooling time. reduce overall production cycle time. Also hot chamber machines quick setup and operation, making them ideal for mass production. Hot chamber machines have a high efficiency production speed and guarantee of high quality for processing products.

2. Shape Intricated Precision Geometies

Zinc alloys have excellent flow characteristics. Can shape intricated geometries and thin-walled parts with precision. Fully fill the cavities of the casting die under high pressure, generates less defects and imperfections. and reduce waste material in mass production. Zinc alloys cast using hot chamber machines can produce superior dimensional accuracy parts and Shape smoother surface finish, call as “As-Cast Finish” which may have a precision dimension and tight tolerance precision.

3. Cost-Effectiveness

The precise injection process minimizes wastage and ensures more consistent parts. Zinc low melting points can also save more energy cost. The hot chamber die casting process have a greater cost-effectiveness.

4. Improved Surface Quality

Using Precision casting die and hot chamber die casting process , lead to excellent surface finishes that often require minimal post-processing. This dues to a good fluidity of zin metal and precision casting dies.

5. Longer Die Life

Zinc’s low melting points reduces thermal wear on dies, prolonging casting die lifespan and reducing tooling costs. meanwhile reduce Zinc Casting Die Maintenance and Repair times.

6. Ease of Automation

Hot chamber die casting machines can be easily integrated into automated production lines. Properly Equipped with robotic hand on the hot chamber die machines , increasing production rate and avoid labor hurt from scald.

7. Environmental Benefits

Zinc alloys are recyclable, and zinc alloy reused again. So this contributes to eco-friendly manufacturing practices. Its mold is precision, without more waste material overflow and waste during mass production. When zinc casting components become useless, and recycle again and reproduce them.

Conclusion

We produce high-quality zinc alloy parts with hot chamber die casting machines requires innovative techniques. By investing in advanced technologies and adhering to best practices, we can achieve exceptional results while maintaining high efficiency and sustainability. The technique Of supporting casting zinc alloy With Hot chamber Die Casting Machines bring our benefits from mass production, either creates much profits or offers more custom die casting components with high quality and conform with international industrial standards. Zinc die casting technology will have a wide market in the future.