Die casting machines that we often see are mostly belong to hot-chamber die casting machines if main products are all made of zinc alloy material in the factory and enterprise. Zinc alloy can be melt and formed into various shape casting parts at lower temperature and melting points. These casting parts cools and solidifies quickly. Ejecting pins them from the die smoothly. gain smoother surface finish parts with high precision and accurate dimensions. All of these, due to advantages for casting zinc alloys with hot-chamber die casting machines.

Content of Table

- What is hot-chamber die casting machine ?

- What are advantages for casting zinc alloy with hot -chamber die casting machines ?

- Conclusion

What Is Hot Chamber Die casting ?

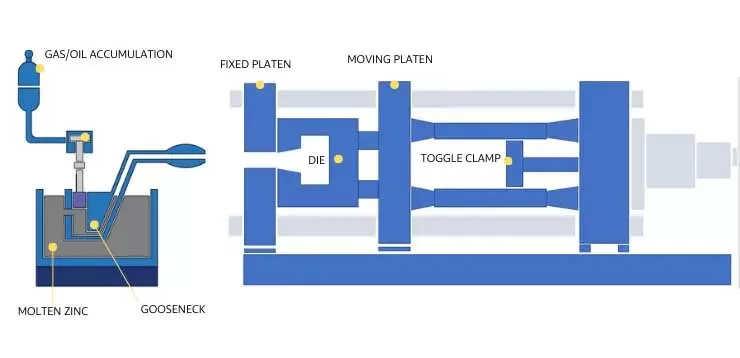

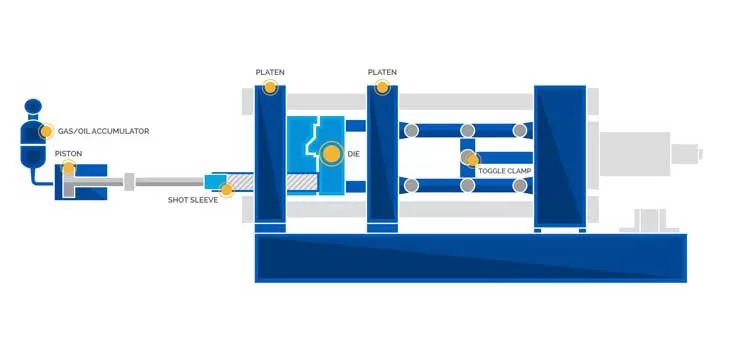

A hot-chamber die casting machine is a type of die casting machine used in metal casting processes, particularly for metals and alloys with lower melting points like zinc, magnesium, and lead. It is one of the two main types of die casting machines, the other type is the cold-chamber die casting machine. The hot-chamber process has unique characters with high effeciency, dimension stability and suitability for high-speed production of small to medium-size casting parts.

Key Components And Process

Furnace/Crucible: Furnace built in the machine, stores the molten metal in an attached furnace or crucible. The metal keeps the liquid state and ready for casting. The furnace works with electricity power, either eco-friendly or hygienic.

Numerical Control Die Machine: Equipped with air cummunlation system, piston hydraulic mechanism and the mold mounted clamp and data control operation screen.

Gooseneck Mechanism: A “gooseneck” mechanism is built-in in the molten metal. The gooseneck serves as the passage to force the molten metal from the furnace to the die, fills the molten metal into the die fully,form the cast part under high pressure.

Injection System: The piston forces the molten metal from the gooseneck into the die cavity under high pressure. This pressure ensures that the molten metal fills entirely the cavity and maintains high dimensional accuracy and smooth surface finish.

Die/Mold: The mold (or die) is a steel cavity and core of the shape for casting part. Once the molten metal fills the die, it cools and solidifies, forms the shape of the part.

Cooling and Ejection: After the molten metal is injected, it rapidly cools and solidifies inside the die. The mold then opens, and eject the cast part out from the mold or die using ejector pins.

Hot-Chamber vs. Cold-Chamber Die Casting

Hot-Chamber

- Used for metals with lower melting points like zinc, magnesium, lead and tin.

- Directly pushing the molten metal is kept in close proximity to the injection system, and form metal part shape.

- Allow a fast cast cycle due to less heat energy consumption and good fluidity for molten metal.

- Longnity steel die and create high precision cavity of the die and high polishing core of the die.

- Suitable for small to medium size metal cast with high precision and multi-functionalities.

Cold-Chamber

- Used for metals with higher melting points like aluminum and copper alloys.

- The molten metal is manually ladled into the injection chamber from an external furnace, leading to slightly slower production speeds.

- Having a longer cast cycle due to more heat consumption for melting the metal and cooling the molten metal.

- Compared shorter longnity steel die because which often works under high temperature and repetitive wear.

- Being ideal for large size cast metal part in mass production and consistent high quality process.

Advantages For Casting Zinc Alloys With Hot Chamber Die Casting Machines

Casting zinc alloys with hot-chamber die casting machines offers several advantages. With the enlargement of zinc die casting parts application range, more custom die casting parts in industrial and automotive components are required to process, becuae zinc die casting benefits from both cost and design of small and medium size metal parts. It includes high efficiency production, cost savings, excellent mechanical properties, and process efficiency. Below are the main advantages.

1. Faster Cast Cycle

Hot-chamber machines have fast cycle times because the molten zinc is directly injected into the mold from an integrated furnace. This minimizes downtime between casting cycles. With less heat energy consumption, Zinc alloys melting time and cooling time is decreased largely, further speeding up cast cycle time.

2. Cost-Effectiveness

The rapid cycle times reduce labor and machine operation costs. Because molten zinc good flow easily and fills molds efficiently, generates fewer rejections and defects, minimizing material waste. Lower energy consumption, which makes the cost of melting zinc and cooling zinc is reduced largely. This makes the process more efficient compared to cold-chamber casting.

3. Create Precise Dimensions And Excellent Surface Finish

Zinc alloys cast with hot-chamber machines offer precise dimensions, allowing complex, intricate shapes and thin-walled parts to produce with less defects. The process results in a high-quality surface finish, which often eliminates the need for extensive secondary machining or finishing operations.

4. Minimal Material Waste

The hot-chamber process allows for the continuous reuse of zinc alloys. Any excess metal can easily recycle, reducing waste and material costs. The precision of the process often produces parts that minimizing flash and supperior surface finish, which reduces scrap material.

5. Compatibility with Complex Designs

Zinc alloys have excellent flow characteristics, which allow for small to medium size casting parts with intricate designs, sharp edges, and very thin walls that might be difficult or impossible to achieve with other metals or processes. The high fluidity of zinc alloys ensures even distribution of the molten metal, resulting in consistent and fewer defective parts.

6. Easy to Realize Automation streamline

Hot-chamber die casting processes are well-suited for automation. It allows manufacturers to apply streamline production, reduce human intervention, and further enhance efficiency and consistent small to medium cast part mass production.

Overall, casting zinc alloys with hot-chamber die casting machines is highly efficient for producing small to medium-sized, high-precision parts, making it a top choice in industries like automotive, consumer goods, and electronics.

Conclusion

Advantages For Casting Zinc Alloys With Hot Chamber Die Casting Machines are highly efficient due to zinc’s low melting point, excellent flow characteristics, fast cycle times and sustainability in the unit process and prolong the life of steel casting die. For industries that require mass production of small to medium-sized, high-precision metal casting components to various demands from different fields. With the rise of AI technology and popularization of intelligence, production automation in industrial manufacturing will experience more intelligent operation. The zinc die casting components mass production remain a consistent and high effective standardation operation.