In our real life, we can touch amazy and appeal metal goods plated by chrome. Among them, some of which are chrome plating zinc die casting products. So today I think that it is necessary to have a brief about zinc die casting plating chrome in further. Here’s an outline and some introductory text for a detailed article on the benefits of chrome plating zinc die casting. I’ll start with the full article, aiming for a focus on chrome plating on zinc die casting enhances durability, aesthetics appeal. protection and appeal that makes these parts more resilient in harsh environments, improving their corrosion resistance, durability, and aesthetic quality.

Understanding Chrome Plating On Zinc Die Casting

Chrome plating on zinc die casting is a widely used surface finishing process. It can enhance the appearance, corrosion resistance, and durability of zinc die-cast components. In this article, we’ll dive into the specific advantages of chrome plating for zinc die-cast parts. It explores what is chrome plating? And chrome plating on the zinc die casting principle.

What is Chrome Plating?

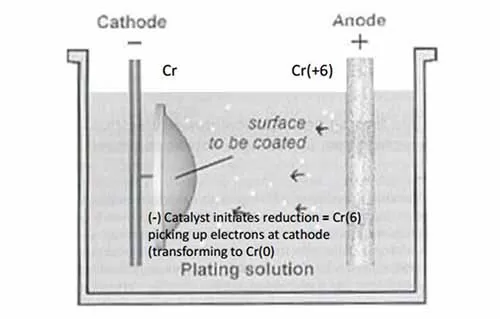

Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal part. A chrome plated part is called chrome, or is said to have been chromed. The chromium layer can be decorative, protective or provide corrosion resistance, facilitate cleaning, and increase surface hardness. Sometimes a less expensive substitute for bond and basic layer, such as nickel, may be used for aesthetic purposes.

This process involves immersing the metal part in a chromium bath and using an electric current to bond the chromium to the metal’s surface. The result is a high-gloss, reflective finish that not only improves the appearance of the metal part but also enhances its functionality.

Chrome Plating On Zinc Die Casting Process

Chrome plating on zinc die casting means coating a thin metal layer on the zinc die castings though chemical reaction, and improving the goods’ aethetics and functionality. The electroplating process includes rough coating can have a better adhesive for chrome plating and protecting coating so that enhancing corrision resistance and wear resistance of the zinc die castings. Detail operation, the follow guideline as showing.

Pre-Treatment and Cleaning

The zinc die-cast part is thoroughly cleaned to remove any dirt, grease, or oxides. This may include ultrasonic cleaning, degreasing, and acid solution treatment. In summary, all dirt on the suface of zinc die casting should be removed completely.

Surface Smoothing

Doing mechanical polishing or grinding to ensure a flawless finish and even areas before plating.

Copper or Nickel Plating

A layer of copper or nickel is often applied before chrome plating. This underlayer provides better adhesion between the zinc substrate and the chrome layer.Enhanced corrosion resistance and uniformity.

Chrome Plating

The component is immersed in a chromium electrolyte solution, and an electric current is applied to deposit a thin, even layer of chrome on the surface of zinc die castings. And prompting corrosion resitance and wear resistance of them.

Post-Treatment

The plated component may couduct additional polishing or passivation to further enhance durability and appearance. the last step of plating chrome. and improve the surface of zinc die casting parts in further. and avoid the chrome plating coating layer peeled.

Benefits of Chrome Plating on Zinc Die Casting

Enhanced Corrosion Resistance

Chrome plating typically involves a multi-layer process, which are the copper layer, nickel layer and chrome layer. These different layers contribut its own function to chrome plating process option. Though their combination functions, Zinc alloys alone offer moderate resistance to corrosion. Moreover Chrome plating acts as an additional barrier against moisture, chemicals, and oxidation, which helps prevent rust and tarnishing over time. This makes chrome-plated zinc die-cast parts ideal for automotive and outdoor applications.

Improved Durability and Wear Resistance

Durability is another significant advantage of chrome plating on zinc die-cast parts. The chromium layer adds hardness to the part’s surface, improving resistance to scratches, dents, and other forms of mechanical wear. The process option may also be used for these components, such as door handles, automotive parts, and industrial equipment. Additionally, chrome plating makes zinc die-cast parts better suited for long-term use. Even in applications that involve frequent handling or friction. For industries that demand high standards of durability and longevity, like aerospace, automotive, and manufacturing.

Aesthetic Appeal and Surface Finish

Some chrome-plated zinc die-cast parts have a mirror-like, high-gloss finish. This finish may be in consumer-facing industries. Such as automotive, electronics, and home hardware, where appearance plays a key role in product desirability. The chrome layer provides a smooth surface that resists tarnishing, dulling, and discoloration. This makes chrome-plated parts easy to maintain, Even with prolonged use. In applications where aesthetics are essential, such as luxury automotive interiors, consumer electronics, and decorative hardware.

Applications For Chrome Plating On Zinc Die Castings

Several industries reap substantial advantages from using chrome plating on zinc die-cast parts, as detailed below.

Automotive Industry: Chrome-plated die-cast parts are a staple in the automotive industry. These essential components like handles, trims, and emblems with both durability and visual appeal. Given the exposure to varying weather conditions and road environments. Automotive parts require resistance to corrosion, scratches, and abrasions that chrome plating can achieve. Our car interiors classic car remote key case cover is a good example.

Consumer Electronics: In the electronics industry, Chrome-plated parts offer a premium feel and are often used in products like phones, laptops, and cameras to enhance their aesthetic value. Such as USB flash drive housing.

Telecommunications and Hardware: The telecommunications industry relies on durable components to ensure reliable performance over extended periods. Chrome-plated zinc die-cast parts are durability and resistance to wear. They are well-suited for devices that need to remain operational under diverse conditions.

Industrial Machinery: Chrome-plated zinc die-cast parts are both durability and precision. They are suitable for industrial machinery where performance reliability and minimal wear are essential. They can withstand heavy use without compromising accuracy, ensuring that machinery runs smoothly.

Conclusion

Chrome plating on zinc die casting, quite enhances durability and aesthetic appeal, in modern industrial equipment and electric consuption goods applications, large zinc die castings chrome plated have been widely used due to zinc alloy specific properties and chrome plate advantages, which withstand strong corrosion and impact, still keep shiny color and noble appearance and luxury features. This is its highlight.