Custom aluminum die casting has become main die casting process. The most commonly material and versatile aluminum alloy for die casting, like A380, A383 AND ACD12. With which, die casting manufacturer can make many aluminum alloy custom die casting parts in automotive and mechanical industries. These Custom aluminum die casting should offer lightweight and strong integrated structure aluminum die casting parts.

The Features Of Custom Aluminum Die Casting

Tailored And Personlized

Custom die casting should be tailored and personalized, until meeting the specific requirement or unique design, the manufacturing process may have an expensive cost, but it can meet the demand of the client, The custom die casting need produce low volume products.

Being Satisfied With Specific Requirement

These Custom die castings require being satisfied with some specific requirement from the client. The aluminum custom die casting parts are used for automotive, aerospace, and other industries needing lightweight components. They need integrated structure and strong mechanical properties.

High Waste Material Acceptable

Custom die casting processes custom die casting parts, may generate more defective products. This causes high waste material during manufacgturing process. So in general term, the client can accept high waste material and pay more money to the supplier. And only require high quality custom die casting components.

Custom Dimensions and Complex Geometry

Aluminum alloy die casting has high dimensional accuracy. Custom die casting need accurate dimensions and specific requirement process, and ensure the accuracy dimensions of the part and personalized geometry requirements. Custom die casting makes the structure and design of mold & die more complex.

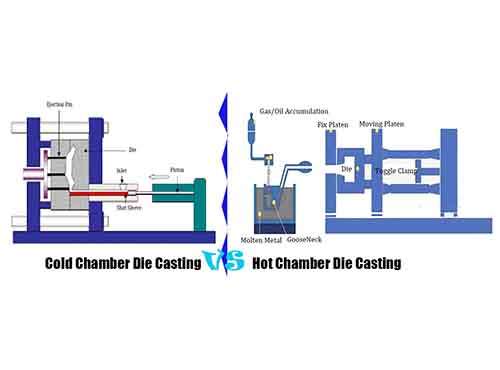

Cold-Chamber Die Casting Machines For Aluminum Alloy

In cold-chamber die casting, the molten metal is melted in a separate furnace. The molten aluminum is ladled into the injection system of the die casting machine when begining casting the aluminum die casting parts. Then injected into the mold using a high-pressure plunger. and cooled and shaped, ejected the shape rough casting components from the die. It needs more heat energy consumption, comparison to hot chamber die casting.

Material Options For Custom Aluminum Die Casting

Die casting manufacturer should select the right aluminum alloy material, follow the specific requirement of the client, with advanced die casting machine and high precision tooling steel die, and process the custom die casting part that being satisfied with the client. Carefully look in the below common aluminum alloys, that is very curicial.

| Aluminum Alloy Items | Composition And Content |

|---|---|

| 2024 | Aluminum (~90%), Copper (Cu): 3.8–4.9%, Magnesium (Mg): 2.1-2.9%, Manganese (Mn): 0.3–0.9%,Iron (Fe): ≤ 0.5%,Silicon (Si): ≤ 0.5%,Zinc (Zn): ≤ 0.25%,Titanium (Ti): ≤ 0.15% |

| 7075 | Aluminum (~88%), Copper (Cu): 1.2-2.0%, Magnesium (Mg): 0.8-1.2%, Manganese (Mn): ≤ 0.3%,Iron (Fe): ≤ 0.5%,Silicon (Si): ≤ 0.4%,Zinc (Zn): 5.1-6.1%,Chromium (Cr): 0.18–0.28% |

| 6061 | Aluminum (~97%), Copper (Cu): 0.15-0.4%, Magnesium (Mg): 1.2–1.8%, Iron (Fe): ≤ 0.7%,Silicon (Si): 0.4-0.8%, Zinc (Zn): 0.25%, Chromium (Cr): 0.04-0.35% |

| 5052 | Aluminum (~96%), Copper (Cu): ≤0.1%, Magnesium (Mg): 2.2-2.8%, Iron (Fe): ≤ 0.45%,Silicon (Si): ≤0.25%, Zinc (Zn): 0.1%, Chromium (Cr): 0.15-0.35% |

| 6082 | Aluminum (~97%), Copper (Cu): ≤0.1%, Magnesium (Mg): 0.6-1.2%, Iron (Fe): ≤ 0.5%,Silicon (Si): 0.7-1.3%, Zinc (Zn): ≤0.2%, Manganese (Mn): 0.4–1.0% |

| 5086 | Aluminum (~94%), Copper (Cu): ≤0.1%, Magnesium (Mg): 3.5-4.5%,Chromium (Cr): 0.05–0.25%, Iron (Fe): ≤ 0.5%,Silicon (Si): ≤0.4%, Manganese (Mn): 0.2-0.7% |

| 1350 | Aluminum (~99.5%), Copper (Cu): ≤0.05%, Iron (Fe): ≤ 0.4%,Silicon (Si): ≤0.1%, |

Custom Aluminum Die Casting: LightWeight And Strong Integrated Structure

Aluminm is lower density metal, in which, it can maintain lightweight die casting part, compare to the other metal, such as zinc, iron, copper and stainless steel. So these aluminum die casting parts are generally used for aerospace and militery defense industries, They are either light weight or having a strong integrated structure. Our engineer suggest that if you want to make high quality custom aluminum die casting process, you must careful design high precision casting die, manufacture the die with high quality tooling steel material. The die should endure high temperature for longer time and high wear resistance in mass production. Also die casting manufacturer should ensure all aluminum die casting part having a strong integrated structure. So custom aluminum die casting: Lightweight and strong integrated structure. Minimizing the porosity status of aluminm die casting part, and enhance the strength of integrated structure of part.