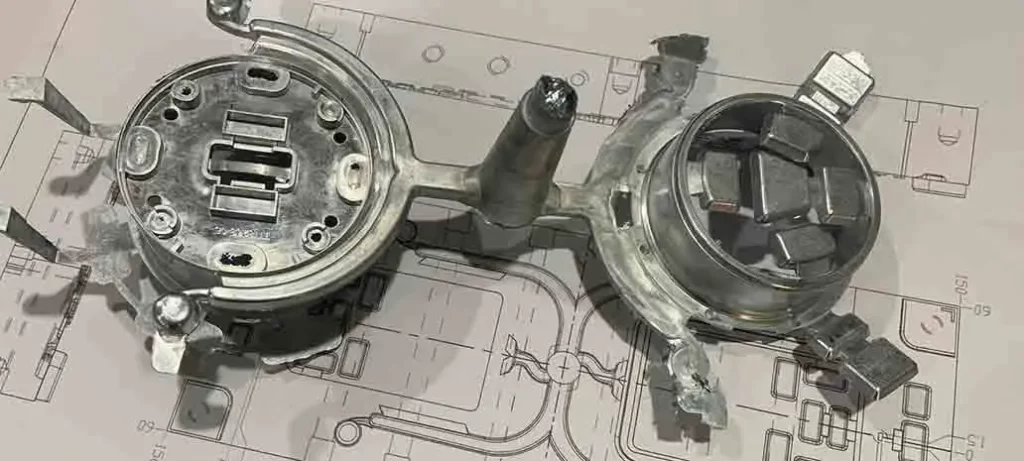

As one of professional die casting manufacturers, we often receive these cases like custom zinc die castings and aluminum die castings for specific applications in many industry. The customer requires some personalized and tailored design plan to aim to the target of the specific application. Our engineering team will collaborate with the client, and finish these custom zinc die casting projects successfully each time. These custom zinc die casting: High Precision And Cost-efficiency. This requires us to provide precise mold tooling steel die, advanced die casting machines, invest well-skilled die casting technician and mass labors and strict quality control.

What Is Custom Zinc Die Casting ?

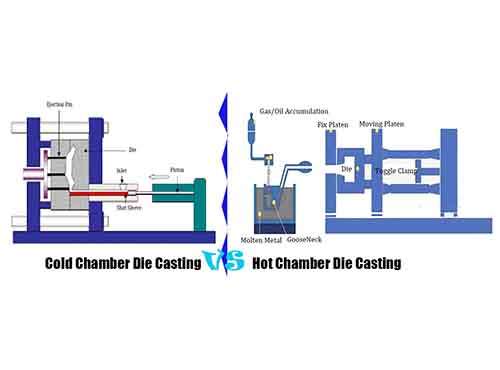

Custom Zinc Die Casting is a manufacturing process that producing the custom die castings depends on the specific requirements or tailored demand from the client. It is suitable for lower melting points metal, Comparison to Custom Aluminum die Casting, which is ideal for process of higher melting points metal. The custom die casting involves of OEM and ODM service projects. OEM project means that the supplier will design the custom casting die and manufacture the casting die and arrange the mass production in the term of product’s drawing offered by the client. However ODM project includes of 3d model of product design, the custom casting die design and manufacturing until finish the mass production. And finish the ODM project. It is called as “turnkey project”.

Custom Zinc Die Casting Process

This should be a simple and straightforward process which injecting the molten metal into metal die under high pressure. Die casting machine drives the plugin to melt metal into the casting die quickly, then forms parts and cools and solidifies shaped parts. As custom zinc die casting , which can form various metal parts at lower temperature. About 420 degree at the temperature.

Custom Zinc Casting Die Design And Manufacturing

Design Phase #

Our work-experienced engineer can design custom zinc casting die with cutting-edges 3d modeling software, like solidwork, ug, ux and CAD. After finishing the design of the mold, they need some mold flow simulation testing tools to inspect the performance of the mold, often use MAGMAsoft and FLOW-3D CAST tools to verify the mold’s performance, and predict some errors in die casting process, and have a troubleshooting for problems ahead. Of course, considering of some of the blew factors that impact custom casting die design.

- Material Selection: Choose the right tooling steel, and have a supperior surface finishing treatment, maybe quenching if necessary.

- Die Component Design: Core, Cavity, Gate and vent channel, molten metal flow channel, cooling system and ejector mechanism.

- Parts Design Factors: Draft angles, Wall thickness, Shrankage allowance, Ejector pins and two halves of mold alignment.

Manufacturing Phase #

After finishing design of the precision custom casting die, engineer transfer the design files into 2d drawing documents, and hand these documents to mold technician for perfect manufacturing. Mold technician will process high hardness steel block into high precision casting die, and pass the below delicate processes.

- CNC milling of die blocks

- EDM (electrical discharge machining) for complex geometries

- High-precision grinding for critical surfaces

- Laser Engraving texture

Zinc Casting Die Trial Testing Phase #

The precision casting die is finishing fabrication, our mold technician have a trial testing for its performance, they install the die on the computer numerical control die casting machine, and set up the cast prameters and begin having a trial cast, and observe and adjust times until casting the qualified prototypes. Record the operation parameters and travel. And maintain the high performance of the die steadily.

- Alloy Selection: Common alloys include Zamak 3, Zamak 5, and ZA-8

- Die Temperature: Typically maintained at 300-400°F (150-200°C)

- Cycle Times: Faster than aluminum due to lower melting point

- Die Life Expectancy: 500,000-1,000,000 shots with proper maintenance

Material Choice For Custom Zinc Die Casting

We choose premium quality zinc alloy material to make high quality zinc alloy custom die casting components. And ensure meeting client’s specific requirements. As one professional metal die casting manufacturer, and possess advanced die casting machines and skilled-well technician and comprehensive quality management system. According to the applications and functions of the custom die castings, we will select the superior raw material among the below material.

Zamak Alloys are most commonly used zinc alloys for die casting. It contains these elements of Zinc, Aluminum, Magnesium, and Copper. Can meet common demands of zinc die casting parts.

ZA Alloys (Zinc-Aluminum Alloys) contains higher levels of aluminum than Zamak alloys, with better mechanical properties. They can be used for some instructural components for automotive engine and heavy industrial equipment.

ACuZinc5 is a high-strength zinc-copper-aluminum. it is cast into higher performance automotive components with excellent wear resistance and strength, also suitable for applications of gears and bushings.

| Zinc Alloy Items | Composition And Content |

|---|---|

| Zamak 2 | Zn (~95.5%), Al (3.8–4.2%), Cu (2.7–3.3%), Mg (0.03–0.06%) |

| Zamak 3 | Zn (~95.5%), Al (3.8–4.2%), Cu (<0.1%), Mg (0.02–0.05%) |

| Zamak 5 | Zn (~95.5%), Al (3.8–4.2%), Cu (0.7–1.1%), Mg (0.03–0.06%) |

| Zamak 7 | Zn (~95.5%), Al (3.8–4.2%), Cu (<0.1%), Mg (0.005–0.02%) |

| ZA-8 | Zn (~91%), Al (8.2–8.8%), Cu (0.8–1.3%), Mg (0.015–0.03%) |

| ZA-12 | Zn (~87%), Al (10.5–11.5%), Cu (0.5–1.2%), Mg (0.015–0.03%) |

| ZA-27 | Zn (~70%), Al (25–28%), Cu (2.0–2.5%), Mg (0.01–0.02%) |

| ACuZinc | Zn (~99.5%), Ti (0.1–0.3%) |

Custom Zinc Die Casting Is High Precision And Cost-Efficiency

Custom Zinc Die Casting Is High Precision

Zinc die casting parts should be made by the precise high quality tooling steel die through advanced equipment and precise technology. It involves of cnc milling, turning, grinding, polishing, cnc machining center and EDM processes .These tight tolerance process ensures the casting die high precision extendition. Since zinc die casting is ideal for miniature metal part, which structural and shape design need more tighter dimensions than larger size metal part from aluminum die casting. So the zinc casting die design become more complex, The tight tolerance is necessary.

Custom Zinc Die Casting is Cost-Efficiency

Zinc die casting parts are easy to make and cost-efficiency, compare to other metal material ,such aluminum , iron and copper. Since aluminum melt point is so high, at about 800 degrees. In another one, melting aluminum alloy material into aluminum liquid in need of much electricity power. However, zinc alloy melt point is 420 degrees or so. From this point, the zinc alloy casting is cost efficiency. Meanwhile, Zinc die casting provides fast cast cycle in mass production. And replacing the workers’ operations with automatic robotic actions and streamline in production.