Many business men require mark their own logos and brands on the goods for better promotion and brand largement of purposes. In order to have a consistent permanent mark on the parts. At the beginning, people printed the logos and brands on the smooth surface of parts with silk screen operation for longer impression for end users and consumers. However after some time, they found that printed logos and brands were wore, lead to fade out easily. For seeking for more effective option, people found that the engraved logos and brands are almost permanence, and not easy to wear and fade out. So laser engraving on the part is best marking option for promotion and brand largement.

What Is Laser Engraving On The Part ?

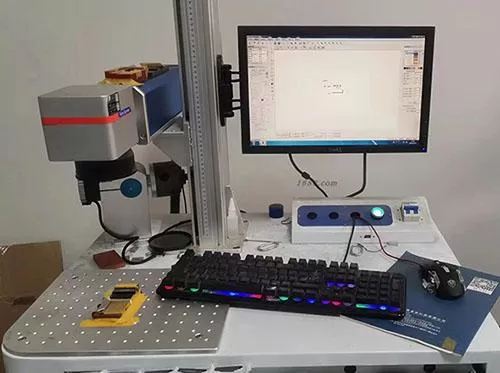

Laser engraving on the part means engineers design 3d engraving vector with computer 3d software, and import the engraving file into the system of laser engraver. Then laser machine foucuses on laser beam light, vaporizes the excess material on the surface of part, and leave high-constract color,permanent logo and pattern. The process is high precise operation action, make the exiquisist logos and patterns with vector files. Also the engraved textures and patterns are not wore and fade out, and durable very much.

Applications For Laser Engraving

Aim to create a clear identificattion on the surface of parts for the purposes of displaying and promotion, laser engraving option have been used widely across many industries. Because laser engraved identification has a high-contrast color and permanemt attributes. and withstand wear and corrosion in air for a long time. let us have a detail description for its applications as the below issues.

Industrial & Manufacturing ( Identification and Traceability)

Aluminum identificational card, on which the properties description for the heavy equipment is engraved permanently. It is mounted on the main position and being convenient to remmond users. Plastic Turnover box used for sorting in many express courrior and logistic,on which tracable number is marked by laser engraving.

Medical & Surgical Devices

Marking scalpel handles, forceps, and clamps with logos, size codes, and lot numbers. The marks must withstand repeated brutal sterilization cycles (autoclaving), and remain the clear pattern, and rightly guide nurse and medical staff to handle them. Some high end orthopedic implant, on which some info and number engraved and trace to source manufacturer and implanting hospital more easier.

Aerospace, Defense & Automotive

Marking assembly number and symbol by laser engraving, help repair man to disattach and install these components. Maybe some warning and important info marked on the part and guide operator to rightly use these components in different work environments. Logos and brands symbol can trace these manufacturer and ensure high quality component supply.

Personalization & Consumer Goods

Silimar with the kind of goods, laser engraving pattern and texture on the surface of goods, which are corrosion and wear resistance. Most of them are used for warning and remmondation repetitively. such as the indicational identification for display panels and warning label for compact consumer electronics. Additional promption purpose for logos and brands of manufacturers.

The Advantages For Laser Engraving

- Permanent Clear: It is vaporite material option; generate engraving surface, making it extremely resistant to wear, heat, solvents, and fading.

- Precision Dimensional Process: Lasers are incredibly accurate, allowing for the engraving of extremely fine details, small fonts, and complex graphics can call be realized.

- Focused beam Light Process: The laser beam never physically touches the part. Different material needs different energy consumption and time. It can mark fragile or irregularly shaped objects without causing damage or stress.

- Versatility: It can be used on a vast range of materials, including metals, plastics, wood, glass, leather, and ceramics. This will contain almost our all daily goods and industrial components.

- Automation & Fast Speed: The process is computer-controlled, making it perfect for high-volume production lines and ensuring every mark is identical. It speed is so fast, and has a high effective production rate.

Laser Marking On Plastic Part

Laser Marking on plastic part is a precise and effective way. It can make permanent markings, logos, or text on the surface of plastic part. Moreover,this laser marking on plastic is clear, wear resistance and durable. Its operation is quite cost-efficiency, compare to Laser Marking On Metal Part . Its operation process is simple, and process-cost is lower.

- Access The Plastic Material And Prepare The Plastic Parts

- Select the Correct Laser Machine

- Set Up the Laser Engraving Machine

- Design the Artwork

- Proceeding the Laser Engraving Process

- Post-Engraving Finishing

Laser Marking On Metal Part

Laser Marking on metal part belong to strong laser beam light engraving option, which require more energy consumption for vaporizing higher melting point metal material, comparison to lower melting plastic material. But also the depth of engravement may spend more longer time and energy consumption. The process is higher cost than laser marking on plastic part.

- Prepare For The Metal Parts

- Choose Right Laser Marking Enquipment

- Design Marking Drawing

- Import Vector Files And Setting Up The Laser Machine Correctly

- Proceed the Laser Engraving Process

- Post-engraving finish and reinforce engraving

Conclusion

Laser engraving is a fast, precise, and permanent method of marking parts whenever plastic and metal parts. Only the different point is volume of energy consumption. Plastic melting point is different from metal one, so metal part laser engraving process exhaust more heat energy than plastic one. But they are all durable and versatile. and can provide promotion and brand largement to more business man and corperations.