Zinc die casting components become more and more commoner in people eye-sight, more manufacturers have gone into zinc casting industry. What they are discussing most is that how they can produce high quality zinc alloy die casting components to meet the demand of the market in recent days. This is an comprehensive issue, which involves of process technique, work experience, labor cost, suitable die casting machine and quality contol. Our experts think that Hot Chamber Die Casting is The Key Technique For Zinc Alloys Casting. It also effectively resolve the key problem of how to produce high quality zinc alloy casting components.

What is Hot Chamber Die Casting ?

The hot chamber die casting is a typical manufacturing technique used to run mass production at high efficiency with low melting metal alloy. By injecting the molten metal into a mold cavity under high pressure, forming intended shape parts with smooth surface finish and tight tolerance dimensions. Common low melting points metal alloys, such as zinc, magnesium, and certain lead and tin alloys.

Hot Chamber Die Casting Process Steps

Interior Furnace

With interior furnace, preheating the casting metal into molten metal. This molten metal is ready to be directly supplied to the die casting chamber. Heat power with electricity power, and eco-friendly and clear, and temperature is stable and melt cast metal fully.

Injection Mechanism

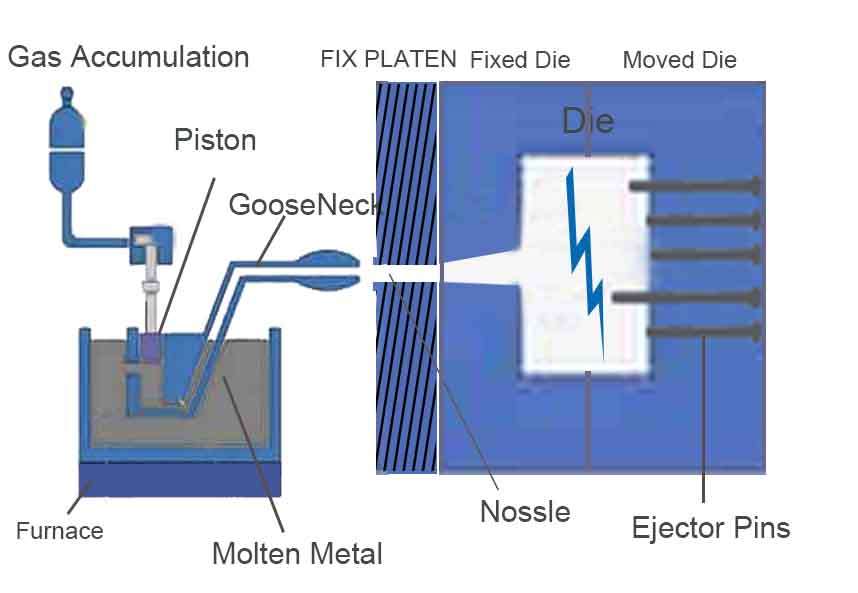

A plunger or piston forces the molten metal through a gooseneck and into the mold cavity. Carrying with the “gooseneck” is submerged in the molten metal with good fluidity. The plunger seals it during the injection process. Under high pressure and ensure the die casting part has a smoother surface finish.

Quick Cooling and Solidification

After injection, the molten metal rapidly cools and solidifies in the mold cavity when the overall casting part is cooled uniformly, shaping the part. This is due to zinc material low melt points and require lower temperature and heat energy, which can cool and solidify quickly.

Part Ejection

Once solidified, the die opens, the casting is ejected from the mold or die by ejector pins. The operation actions are fully automated, controlled by digital program. Proper angle draft design is neccessary and ensure the fine cast parts seperate from the casting die smoothly and reduces defective parts.

Fast Cast Cycle

The process is highly automated and fast cast cycle, allows a rapid cast cycle. It is suitabel for a high volume production, and helpful to raise production rate and products quantity without any compromising high quality. Automatic production line saves more labor cost and reduces humen hurt largely.

Advantages of Hot Chamber Die Casting

- High Efficiency Productive rate: The integrated injection mechanism allows quick and continuous production cycles for lower melting point metal alloys.

- Precision and accuracy: Produces parts with excellent dimensional accuracy and fine surface finishes with high precision tooling steel die and numerical control die casting machine.

- Being Ideal for Small to Medium Parts: Ideal for mass production of small to medium-sized parts with thin walls. Provide intricate structural parts and complex appearance with accurate dimensions

- Material Unique Properties: Well-suited for metals with low melting points and high fluidity, such as zinc,magnesium,lead and tin alloys.

- Less Heat Energy Consumption: The process need less heat energy to melt the metal alloy, and the formed metal part can cool and solidify in shorter time, and save more energy consumption. especially energy consumption for electrical power furnace.

Hot Chamber Die Casting is Key Technique for Zinc Alloys Casting

Producing Zinc Alloy Casting Components Needs Key Technique: Hot Chamber Die Casting Process, which offers high efficiency and precision and intricate metal die casting components. Especially mass production for intricate and small and medium sizes of zinc parts. So The Technique Of Supporting Casting Zinc Alloy With Hot chamber Die Casting Machines had become so essential.

Zinc Alloys Belong To Low Melting Point Metal and Good fluidity

Zinc alloys, with their relatively low melting points, are perfect for the hot chamber process. The integrated melting system ensures a seamless flow of molten metal into the mold cavity. With additional melton zinc’s good fluidity, ensure the surface finish of die casting part is more smooth.

Fast Cast Cycle

Equipped with interior furnace, preparing for stable melton zinc in the melton pot and less heat energy consumption, makes the rapid solidification of cast part. High automated operation enables the production of a high volume of components with consistent quality.

Precision And Complex Design

Molten zinc alloys have excellent fluidity. Under high pressure ensures the creation of parts with thin walls, complex geometries, and fine surface finishes. These cast parts are critical for automotive, communication, and other industries.

Material Efficiency And Sustainable Development

Zinc’s recyclability and minimal waste generation in modern manufacturing. It also conform with goals of sustainability and cost-efficiency in global green health environment.

Lower Production Cost

Zinc alloy has a lower melting point, lead to saving more thermal energy during heating the metal. Meanwhile reducing the die casting cooling and solditifying time during processing the die casting part. Whenever production time ,or energy consumption and labor cost, these save more production cost.

The Key Technique for Zinc Alloys Casting Creates Fine Surface finishing

Ensure components have fine surfaces ready for post-processing like plating or painting.

By Properly using the hot chamber die casting process, we can produce high-performance zinc alloy components that meet the demands of diverse applications while maintaining cost-effectiveness and sustainability. The above helps us to explain the reason that Hot Chamber Die Casting is Key Technique for Zinc Alloys Casting in detail. Other key techiques are neccessary if the consistent high quality mass production should be conducted.

Conclusion

Choosing Hot Chamber Die Casting Process to Produce Zinc alloy Casting Components. We will produce high quality zinc alloy die casting component, which is not only suitable for client’s requirements and functionality, but also can raising production effective and production quantity. As this technique advancement, we can be satisfied with custom demand and special requirements from business partner and individual and personalized order. Under at lower cost, producing a high volume high quality zinc die casting components for industry and market all over the world.